When purchasing a vibrating screen, don’t forget to check its structure from its screen areas, layer numbers, size, shape, and area ratio, as well as the vibration frequency, motion mode, and amplitude.

The number of decks of vibratory screen

The Incline Style Vibrating Screens are available in single, double, triple and quad decks. These screens can be designed and equipped with several mechanism sizes and options that include single, dual or triple drives to give you maximum efficiencies and bearing life. Three decks are pretty common in the aggregate industry, but the number of screen decks depends on the number of products the site needs to make.

Coarsest mesh specification on the top deck and the finest specification on the bottom deck. As the vibrating screen machine operates, materiel will continue to hit screen media, bounce, and pass through the openings until the particles are too large to pass.

Each screen deck is covered with screen media containing the openings for the particles to pass through. Screen media comes in many different forms, and the type of screen media plays an important role in screening efficiency.

Read More: Guide to the Best Vibrating Screen in 2022

Determine the screen openings

First to consider is the opening of a screening surface because it influences the overall efficiency of the material separation process. The more openings in the screen, the more opportunities particles will have to pass through – and the more efficient the screen will be.

More openings in a screen can decrease the wear life of the media. The correct screen media for an application will balance both wear life and efficiency. Therefore, the design of the screening surface highly affects the equipment’s overall efficiency at separating materials, it can determine the screen capacity by considering the ratio between the hole area and the screening surface, and it is decrease the space between the holes to increase the screening surface to enhance the equipment’s capacity.

Common types of screen media for aggregate applications include woven wire, polyurethane, rubber and hybrid. Remember to consider the nominal size of the screening mesh and the size of the mesh itself, because there’s a chance for materials to be congested on the screening surface and the near-size particles passing through the mesh might reduce.

Vibrating screen media

- Woven wire: Wove wire cloth is the most consistent, versatile media product. It averages 50 to 70 percent open surface area in most configurations and provides flexibility for operations that need to make frequent media changeouts due to varying product specifications. Overall, screening efficiency is good with this type of media.

- Polyurethane: Polyurethane is better suited for wet or wash screens and dry applications with highly abrasive materials. It provides 30 to 40 percent less open area than wire cloth, but polyurethane offers extended wear life over wire media.

- Rubber: Rubber media is used for heavier, coarser materials that can damage standard wire screens. It is most often used for dry applications or abrasive materials. Rubber media has fewer openings than wire cloth, therefore delivering less throughput. It can, however, last much longer than wire screens.

- Hybrid: Hybrid media combines a wire screen with reinforced rubber, or urethane strips, to fit screen supports. It is highly popular in dry-screening applications with high-moisture materials and a high proportion of fines. Hybrid media provides more open area than polyurethane and lasts longer than woven wire.

Depending on the application, production can increase 40 percent using hybrid screen media.

Check the Particle Shape

Next is the shape of the particles that are fed into the machine, which affects the sizing of the vibrating screen. You need to make sure that you know what materials will be passing through the machine. This is crucial to determine the properties of the particles first because a particle’s shape will affect your vibrating screen selection.

Distribution of Material

Material distribution focuses on the discrete material sizes in a given feed steam of a vibrating screen. When buying a vibrating screen, you’ll need to figure out the percentage of material to help you choose the right vibrating screen. Remember, the more material is required to pass through the equipment, the larger your screen should be to easily lodge the materials.

Density of Material

Except for material distribution, your material’s density should also be considered when selecting the right vibrating screen to enhance maximum efficiency. The density is described as the bulk amount and load the equipment has to carry.

Screen Length

Choosing a vibrating screen with increased screen length helps your production to be more efficient, as it allows a longer time for near-sized materials to pass through the screen. In addition, every material and application requires various screen lengths, which entirely rely on the material’s properties.

Screen Purpose

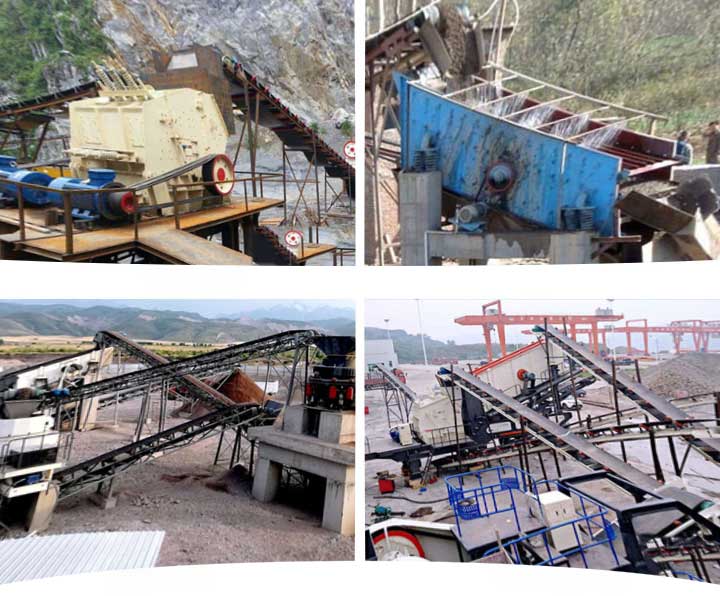

Each vibrating screen has different screen purposes. For instance, if you’re looking for a type to pre-screen materials, you can use a circular vibrating screen. For crushed or grading materials, opt for large-scale vibrating screens. When it comes to dehydrating the materials, you can choose a linear vibrating screen. And, for sand cleaning of materials, it’s better to choose probability screens.

Screen Structure

Finally, it’s important to set your eyes on the structure of the vibrating screen you’re looking for. Does it have an appropriate screen area, number of layers, size, shape, and rate of the screening hole? Does it have an accurate motion mode, vibration frequency, and amplitude that is suitable for your material?

Apron feeder or belt feeder

The standard belt feeder is perfect for sand and gravel operations, but it is likely to tear or break when working with metal, large rock or extremely abrasive material. An apron feeder, which is essentially a belt made of metal, is durable and can handle nearly anything operators throws at it.

Works Cited: What are the factors to consider when choosing a vibrating screen?