China Vibrating Conveyor Manufacturers

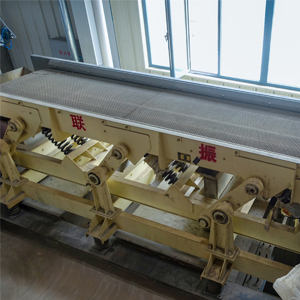

vibrating conveyor

UHM Vibratory Machinery – Experts in Vibratory Conveyors. UHM Has 20+ Years of Experience in Conveyor Vibration Systems, Vibrating Screening, Vibrating Fluid Bed Dryer, and Vibrating Feeder.

What is a Vibratory Conveyor?

UHM: Experts in Conveyor Vibration System. Have 30+ Years of Experience in Vibrating Conveyors.

The vibrating conveyor (also called vibratory conveyor or vibration conveyor, or vibrating feeder conveyor) is a continuous vibratory conveying machinery that uses a vibrator to vibrate the trough so that the material in the trough slides or moves in a certain direction. It is generally used for horizontal conveying, the productivity is less than 150t/h, and the conveying distance is less than 80m. When inclined upward, productivity decreases with the increase of the inclination angle.

Advantages: The vibrating conveyor has the advantages of simple structure, convenient installation and maintenance, low energy consumption, no dust spillage, and low noise.

Application of Conveyor Vibration System?

Conveyor Vibration System (Vibrating Conveyor) except for some parts of the vibration excitation mechanism, there are few relatively rotating parts, and the structure is simple, which can transport materials of various particle sizes, and can carry out closed transportation of hot, flammable, explosive, toxic and dusty materials.

The vibrating conveyor is not suitable for conveying viscous materials.

Five Components of a Vibrating Conveyor

Components 1#: Vibrating Conveyor Chutes and Balanced Underframes

The vibrating conveying trough and the balanced chassis are the two main components of a vibrating conveyor system. The trough transports materials, and the underframe mainly balances the inertial force of the trough and reduces the dynamic load transmitted to the foundation.

Components 2#: Exciter

The exciter is the power source of the vibrating conveyor and produces a periodically changing exciting force, which makes the conveying trough and the balanced chassis produce continuous vibration. It can be divided into mechanical, electromagnetic, hydraulic, and pneumatic types. The size of its exciting force directly affects the vibration amplitude of the conveying trough.

Components 3#: Main Vibration Spring and Vibration Isolation Spring

The main vibration spring and vibration isolation spring are the elastic elements in the vibrating conveyor system. The function of the main vibration spring: the main vibration spring supports the conveying trough and is usually installed obliquely, and the oblique angle is ß (vibration angle). , Effective use of vibration energy. The function of the vibration isolation spring: support and reduce the dynamic load transmitted to the foundation or structural frame.

Components 4#: Guide Rod

The function of the guide rod is to make the tank body and the bottom frame vibrate relative to each other along the center line perpendicular to the guide rod, and it is connected with the tank body and the bottom frame through a rubber hinge.

Components 5#: Feeding Device and Unloading Device

The feeding device and unloading device are used to control the material flow and are usually softly connected to the tank.

Two Types of Vibrating Conveyors

Vibrating conveyors can be divided into two types: mechanical type and electromagnetic type according to the excitation mechanism.

The mechanical type can be divided into elastic connecting rod type and inertial type;

According to the number of vibration components, it can be divided into three types: single-mass body, double-mass body, and multi-mass body types.

Only the conveying trough of the single-mass body vibrates, so the vibration force is transmitted to the foundation, and most of them are light;

In addition to the conveying trough of the two-mass and multi-mass bodies, there are counterweights participating in the vibration, the structure is slightly complicated, but it can basically Eliminate the vibration force on the foundation, and use the principle of resonance to minimize the required excitation force.

- Elastic connecting rod type: It is composed of an eccentric shaft, connecting rod, spring at the end of connecting rod, and material trough. The eccentric shaft rotates so that the reciprocating movement of the end of the rod excites the trough for directional vibration. Promote the material in the tank to move forward continuously. Generally, low frequency, large amplitude or medium frequency, and medium amplitude are used.

- Electromagnetic type: It is composed of an iron core, coil, armature, and trough. When the rectified current passes through the coil, a periodic electromagnetic attraction is generated, which excites the trough to vibrate. Generally, high frequency and small amplitude are used.

- Inertial type: It is composed of an eccentric block, main shaft, trough, etc. The centrifugal inertial force generated when the eccentric block rotates arouses the vibration of the trough. Generally, medium frequency and amplitude are used.

Application of Conveyor Vibration System?

Conveyor Vibration System (Vibrating Conveyor) except for some parts of the vibration excitation mechanism, there are few relatively rotating parts, and the structure is simple, which can transport materials of various particle sizes, and can carry out closed transportation of hot, flammable, explosive, toxic and dusty materials.

The vibrating conveyor is not suitable for conveying viscous materials.

Widely used in metallurgy, coal, building materials, the chemical industry, food, and other industries for conveying powdery and granular materials.

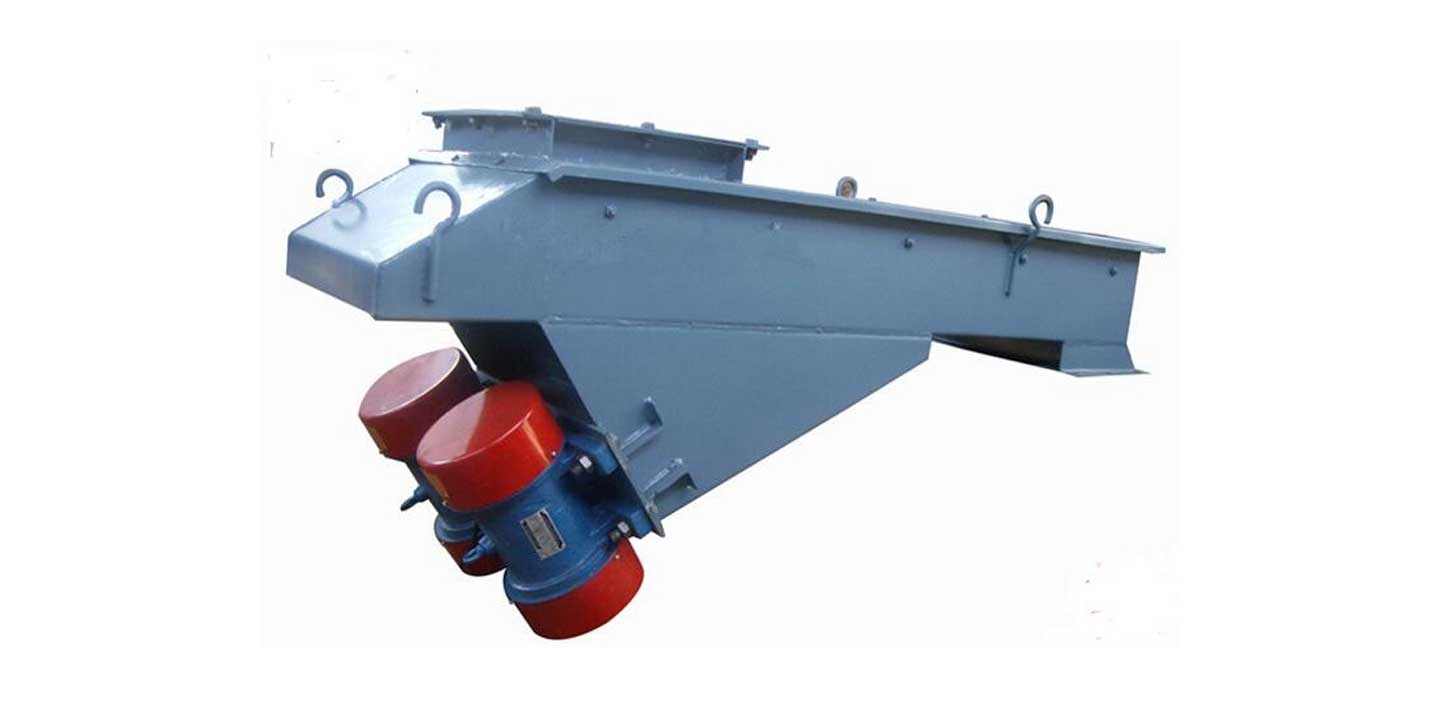

conveyor vibration system

About UHM

Nantong United Heavy Machinery Co., LTD(UHM) has always been an innovative pioneer in the technological development of vibrating machines, such as vibrating feeders, conveyors, screening, and drying. We now have more than 100 skilled and experienced staff members. The management system is certified by ISO9001: 2015 standard. To provide more professional and closer services to our customers in the sugar industry, we established a special team consisting of more than 30 experienced persons.

UHM is not only an equipment manufacturer but also a solution provider. Questions no matter whether bulk & granular or powder material processing, our experienced engineers are always able to offer the best solutions.

NEWS & EVENTS

Vibrating Screen Blinding: 5 Reasons and 9 Solutions

What is a vibrating screen blinding? Material plugging often occurs in the use of a mining vibrating screen. There are several reasons for screen plugging as the shape of the material varies. Plugging…

Screw Feeders vs. Vibrating Feeders: Pros and Cons

This article will introduce the advantages and disadvantages of the screw feeder and vibrating conveyor to you, let’s take a look together! Vibrating Conveyor Composition Practical and easy to u…

5 common vibrating screens and their introduction

Screening is one of the most important parts of aggregate production. It takes place before and/or after the crushing stage (or stages) and produces the specifications required for the final products.…