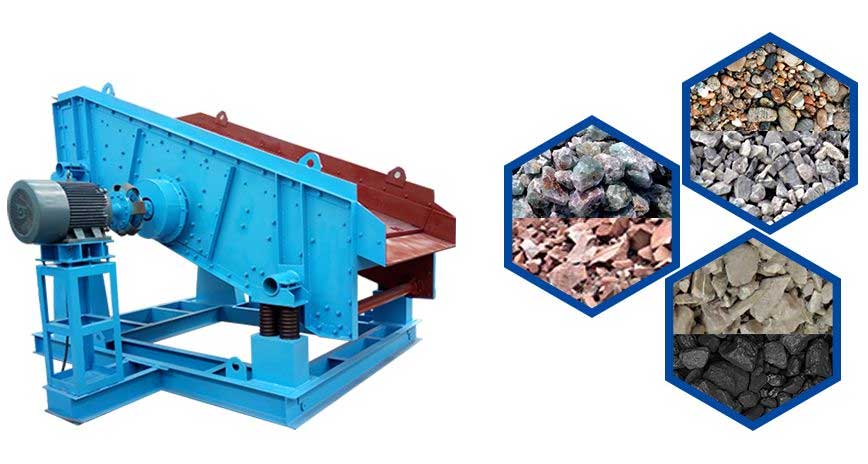

Vibrating Screens

- The main components of vibrating screens are: Screen body, Screen mesh or sieve, Vibration source, Base frame, Triangle belt, Electric motor, Driver eccentric, and More (model dependent).

- The works principle of vibrating screens: The driver eccentric moves because of an electric motor. It revolves rapidly through a triangle belt with a centrifugal force that stimulates a sieve to move circularly. The materials on the sieve receive the impulse so that the sieve provides a throwing movement on screening surfaces. The material becomes reduced in size as it passes through the screen mesh. The steep angle of the throw prevents mesh blinding and permits maximum efficiency.

Read More: Guide to the Best Vibrating Screen in 2022

Circular Motion vs. Linear Vibrating Screens: Who is More Popular?

The more commonly used types in mine production are circular motion vibrating screens and linear vibrating screens. While the working principles of the two types of vibrating screens are similar, movement is the primary difference.

The more commonly used types in mine production are circular motion vibrating screens and linear vibrating screens. While the working principles of the two types of vibrating screens are similar, movement is the primary difference.

4 Features of circular Motion and linear vibrating screens

Optimum separation sharpness for outstanding process results.

Available in single-deck and double-deck designs, enabling safe and fast screen and motor changes.

The screens of screeners are available in flexible machine working widths and screen deck lengths.

Highest availability and production reliability.

Compact and dust-tight design.

Who is More Popular?

- Typically, circular motion vibrating screens are more popular, and their movement cycle and operation are more complex.

- Since circular motion screeners come in several versions, they can be used to screen wet, dry, coarse, or fine particles, which makes them more suitable for a wider range of applications.

Read More: Buying Guide for Linear Vibrating Screen

Top 5 major differences between circular motion and linear vibrating screens

There is no essential difference between the style and structure of the circular motion vibrating screen and the linear vibrating screen. The materials are screened through the vibration of the screen surface, but the difference in the vibration track will directly affect the screening purpose. Once you know the fundamentals of mechanical screening, the next step is choosing a vibrating screen based on the industry you’re in and what materials you need to feed through the equipment. Read more to learn the top 7 major differences between circular vibrating screens and linear vibrating screens.

Differences 1#: Works Priciple

- The circular motion vibrating screen is also called a single-axis vibrating screen because the exciter is a shaft and uses an inertial motor to work. Circular Motion Vibrating Screen is a screening system that is set into circular or optionally counter-rotating vibration by an unbalanced motor. The material of the circular motion vibrating screen moves in a parabolic circular trajectory on the screen surface, so that the material is dispersed as much as possible, thereby improving the bouncing of the material and reducing the phenomenon of the hole blocking.

- The linear vibrating screen vibrator is composed of two shafts and works on the principle of vibrating motor excitation, so it is also called a double-axis vibrating screen. A linear vibrating screen is a free-swinging screen It uses a vibrating motor to throw materials in an upward and forward linear motion. The material of the linear vibrating screen moves smoothly on the screen surface. If the feeding is uneven or the material has high humidity and viscosity, it is easy to block the hole.

Differences 2#: Functionality of material screening

- A linear vibrating screen is that its motion is linear. It uses a vibrating motor to throw materials in an upward and forward linear motion.

- Circular Motion Vibrating Screens with twin-vibrating motors that function in a synchronized fashion and move the centrifugal force parallel to the motor access. Centrifugal and gravity force help throw the material in the direction it moves, which effectively reduces its size and grades it.

Differences 3#: Installation

- Generally speaking, the inclination angle of the screen surface of the linear vibrating screen is small, and the height of the screen surface is reduced, which is convenient for layout.

- The circular motion vibrating screen is usually installed with an inclination angle of 15-20 degrees to change the moving speed of the material along the screen surface and improve the screening efficiency.

Differences 4#: Processing capacity per unit of time

- The linear vibrating screens are available in single and double-deck designs and are excellent for control and protective screening, and can adopt a fully enclosed structure without dust spillage, which is more conducive to environmental protection.

- The exciter of the circular motion vibrating screen is arranged above the center of gravity of the screen box, effective product loosening is effected in the inlet area with simultaneously increased residence time in the outlet area, and the processing capacity per unit time is higher than that of the linear vibrating screen. The circular vibrating screens are also available as single and double-deck designs and are mainly used for high separation efficiency in the medium and coarse grain range.

Read More: Buying Guide for Circular Motion Vibrating Screen

Differences 5#: Typical applications

- The circular motion vibrating screening material is relatively thick, and the box body is made of manganese steel, which can resist the impact of the material during the screening process. Circular motion vibrating screens comes in several versions, it can be used to screen wet, dry, coarse or fine particles, which makes it more suitable to a wider range of applications. Several industries that rely on screening from this machinery are mineral beneficiation plants, mining, food and fertilizer manufacturers, coal preparation plants, steel mills and more.

- The material of linear vibrating screening is mainly a light plate or stainless steel plate. Linear vibrating screens are known for being rugged, stable and simple to maintain. Typical applications include primary and secondary classification, sizing, de-sliming, washing, dewatering and hot-material screening, among others.

Works Cited: high-frequency vibrating screens wikipedia