Bucket Conveyor Manufacturer

NE Bucket Elevator/Bucket Conveyor

NE bucket elevator using plate chain traction inflow feeding, gravity-induced feeding, no return phenomenon.

NE Bucket Elevator/Bucket Conveyor

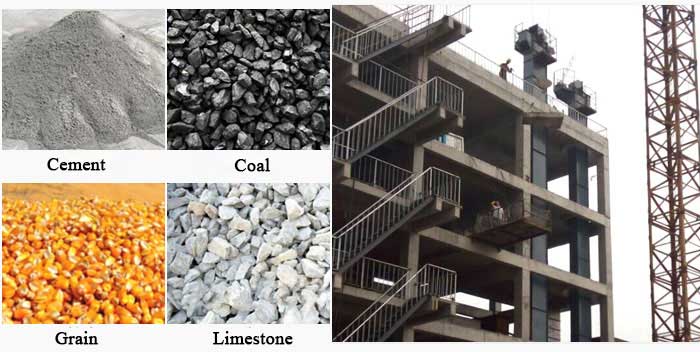

NE bucket elevator using plate chain traction inflow feeding, gravity-induced feeding, no return phenomenon; can vertically transport powdery, granular, small abrasive or non-abrasive materials

- Lifting capacity: 15-800 cubic/hour

- Lifting height: 40 meters

NE-type bucket elevator produced by Nantong Lianzhen Heavy Machinery for plate chain, gravity-induced discharge of lifting equipment. NE-type bucket elevator for vertical conveying powder, granular, small block, abrasive or non-abrasive materials, such as raw materials, cement, coal, limestone, dry clay, clinker, etc. Read More: Bucket Conveyor Wikipedia

Read More: Bucket Elevator, Bucket Conveyor, Best Beginner’s Guide

Top 3 Features of NE Bucket Elevator

- NE-type bucket elevator plate chain machine has a higher shear strength, fatigue strength, and wears resistance, running low failure rate, and long service life;

- NE-type bucket elevator chain using low speed (0.5 m / s);

- NE-type bucket elevator buckets use a large hopper capacity and a smaller pitch, drive power is low, and transmission capacity. NE-type bucket elevator is particularly adapted to enhance the limestone and cement clinker after crushing (≥NE50)

Working principle of bucket elevator

The hopper of the plate chain bucket elevator scoops up the material from the lower silo, lifts it to the top with the chain, bypasses the top wheel, and then flips down to pour the material into the receiving tank. The chain-driven bucket elevator is generally installed There are two parallel drive chains, with a pair of drive sprockets on the top or bottom, and a stack of redirection sprockets on the bottom or the top.

5 main structures of NE bucket elevator

- Running parts: composed of hopper and sleeve roller chain;

- Driving device (left and right assembly): composed of a driving platform, a driving combination (reducer, motor, hydraulic coupling device), and a transmission chain;

- Upper device: upper casing, upper cover, discharge port, upper shaft device, backstop;

- Middle casing: standard section (2m) and non-standard section (1~1.5m), including the middle section with inspection door;

- Lower device: lower casing, feeding port, tail shaft device, tensioning device.

Specifications of NE Bucket Elevator

| Model | Conv Cap m3/h | Speed m/s | Main Shaft RPM r/min | Particle Size mm | Hopper volume L | Hopper width mm | Hopper distance mm | Weight kg/m |

| NE15 | 15 | 0.5 | 15.54 | ﹤40 | 2.5 | 250 | 203 | 27.5 |

| NE32 | 32 | 0.5 | 16.45 | ﹤50 | 7.8 | 300 | 305 | 35 |

| NE50 | 60 | 0.5 | 16.45 | ﹤50 | 15.7 | 300 | 305 | 64 |

| NE100 | 110 | 0.5 | 14.13 | ﹤70 | 35 | 400 | 400 | 89 |

| NE150 | 170 | 0.5 | 14.13 | ﹤70 | 52.2 | 600 | 400 | 112.3 |

| NE200 | 210 | 0.5 | 10.9 | ﹤100 | 84.6 | 600 | 500 | 134 |

| NE300 | 320 | 0.5 | 10.9 | ﹤100 | 127.5 | 600 | 500 | 188 |

| NE400 | 380 | 0.5 | 8.3 | ﹤120 | 182.5 | 700 | 600 | 205 |

| NE500 | 470 | 0.5 | 7.1 | ﹤120 | 260.9 | 700 | 700 | 223 |

| NE600 | 600 | 0.5 | 7.1 | ﹤120 | 330.2 | 700 | 700 | 274 |

| NE800 | 800 | 0.5 | 6.2 | ﹤140 | 501.8 | 800 | 800 | 313 |

Application of NE bucket elevator

Plate chain bucket elevator is mainly suitable for conveying raw meal, cement, coal, coke, limestone, dry clay, clinker, gravel, sand, fertilizer, grain, and other powdery, granular, small abrasive, or non-abrasive Abrasive materials. It is widely used in mining, metallurgy, building materials, coal, hydropower, cement, and other industries to vertically lift lumpy and powdery materials whose temperature does not exceed 250°C.

Nantong United Heavy Machinery Co., LTD(UHM) has always been an innovative pioneer in the technological development of vibrating machines, such as vibrating feeders, conveyors, screening, and drying. UHM is not only an equipment manufacturer but also a solution provider. Questions no matter whether bulk & granular or powder material processing, our experienced engineers are always able to offer the best solutions.