vibrating conveyor manufacturers

vibrating conveyor systems

Types of Vibratory Conveyors

Mechanical vibrating conveyor and Electromagnetic vibrating conveyor.

The mechanical type vibrating conveyor can be divided into elastic link type and inertia type; according to the number of participating vibration members, it can be divided into elastic link & inertia type; Or it can be divided: into single, two-mass, and three-mass vibratory conveyor systems.

Single-Mass-System Vibrating Conveyor: only the trough produces vibration, so the vibration force is transmitted to the foundation, which is mostly light;

Resonance Vibratory Conveyor Two-Mass-System and Resonance Vibratory Conveyor Three-Mass-System (fully balanced vibrating conveyor): In addition to the trough, there are also counterweights participating in the vibration, the structure is slightly complicated, but the vibration force on the foundation can be basically eliminated, and The resonance principle is used to minimize the required excitation force.

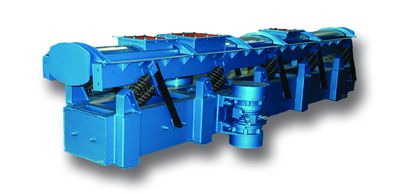

Dynamically balanced vibratory conveyor systems

Three-Mass Vibratory Conveyor System

- Fully balanced

- No external balance beams

- Adjustable stroke/variable speed

- Eccentric drive shaft

- PSL Dynamically balanced vibratory conveyor is developed on the basis of the plastid resonance type of a new type of vibrating conveyor

- Besides has the advantages of the plastid resonance type

- The most prominent advantage is passed to the base of inertial vibration (dynamic load) is very small

- Low noise, suitable for long, wide groove width of transport requirements, when the floor surface or on steel structure installation with other types of vibrating conveyor incomparable shock absorption edge.

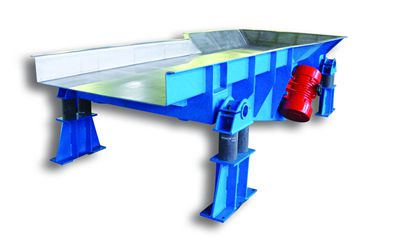

Double mass resonance type vibrating conveyor

Two-Mass Vibrating Conveyor

- Fully balanced

- No external balance beams

- Adjustable stroke/variable speed

- Eccentric drive shaft

- Rigid and simple structure, lower consumption of power.

- The total height is low and suitable for the limited room.

- Multiple applications can easily be achieved.

- Also suitable to be mounted on stairs, steel structure platforms, etc.

- Easier maintenance and lower cost.

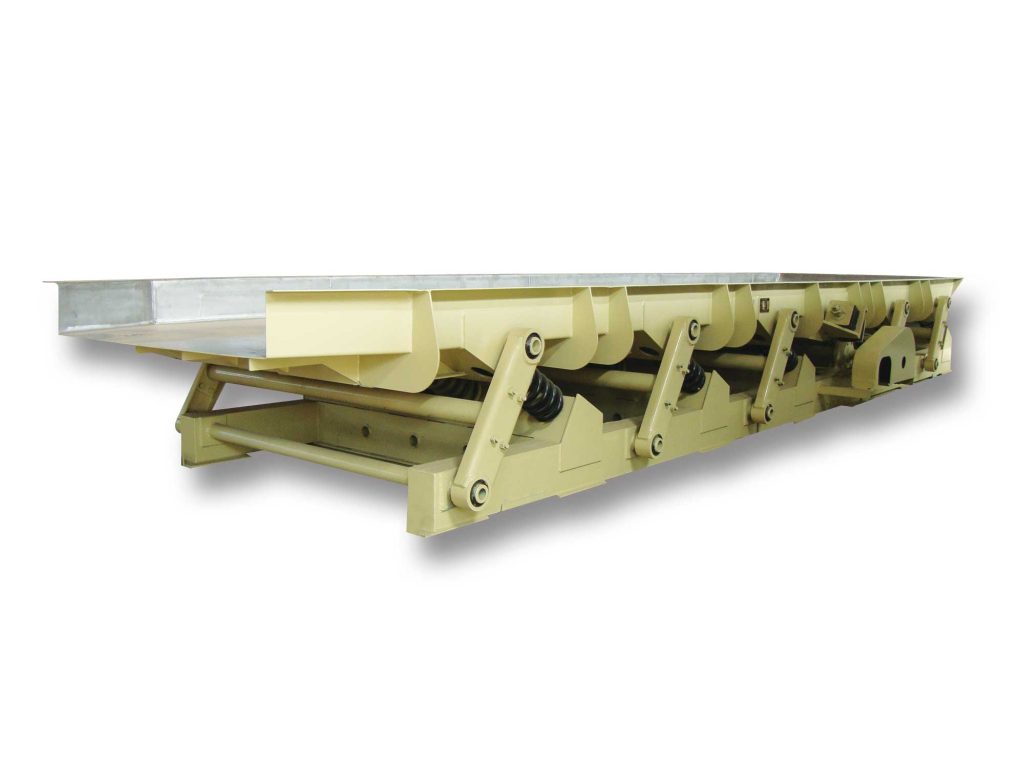

Single mass vibrating conveyor

Vibratory Conveyor

- High stiffness and simple structure, suitable for long-distance and quick conveying.

- The total height is low and suitable for the limited room.

- Multiple applications can easily be achieved.

- Single conveyor length can reach 25 meters and proved to be feasible.

- Highly Reliable, Easier Maintenance, and Lower Cost.

SZF heat inertia vibrating conveyor

High-Temperature Vibrating Conveyor

SZF type heat inertia vibration feeding conveyor (high temperature vibrating conveyor system) is a kind of long-distance conveying equipment of both lock functionss of the wind.

The high temperature vibrating conveyor is suitable for conveying various secondary fragmentation and horizontal conveying powder and granular materials under high temperature (500 ℃) or less high abrasion materials, such as baking hot slag thermal material, cement, etc.

Motor Vibration Conveyor

DZS type motor vibration conveyor, conveying groove for the u-shaped slot and tubular.

The bottom of the channel can be changed to the tilting, the groove can be sealed, can be made into a feed multipoint discharge, or multipoint feeding discharge, discharge mouth can be vertical, side slope form or under bending, discharging mouth valve can be set up various forms. Can be set up multiple conveying or add layer mesh screen. Equipped with a variable frequency regulator, the operation of the speed control can be realized.

What is a vibratory conveyor?

The vibrating conveyor is a continuous conveying machine that uses a vibrator to vibrate a trough so that the material in the trough slides or is thrown in a certain direction.

Where vibratory conveyors are used?

Generally used for horizontal transportation, the productivity is less than 150t / h, the conveying distance is less than 80m, and the productivity decreases with the increase of the inclination angle when the vehicle is tilted.

In addition to some parts of the vibration mechanism, there are a few relative rotating parts, a simple structure, that can transport materials of various sizes, and can carry out closed transportation of hot, flammable, explosive, toxic, and dusty materials. Process operations such as screening, dewatering, and cooling can be performed simultaneously during transportation.

However, it is not advisable to transport sticky materials.

Vibrating Conveyor Components

- Resonance Two-Mass-System or Three-Mass-System Vibratory Conveyor: It consists of an eccentric shaft, a connecting rod, a connecting rod end spring, and a trough. Eccentric shaft rotation. The end of the rod reciprocates to excite the trough for directional vibration. The material in the tank is continuously moved forward. Low frequency, large amplitude, or medium frequency and medium amplitude are generally used.

- Inertial vibrating conveyor: It consists of an eccentric block, the main shaft, a chute, etc., and the centrifugal inertial force generated when the eccentric block rotates excites the chute vibration. Medium frequency and amplitude are generally used.

- Electromagnetic vibrating conveyor: It consists of an iron core, coil, armature, and trough. When the rectified current passes through the coil, a periodically varying electromagnetic attraction is generated, which causes the chute to vibrate. Generally, high frequency and small amplitude are used.

Working principle of vibrating conveyor

The vibrator of the vibrating conveyor vibrates the trough, and the trough body is subjected to directional forced vibration under the constraint of the main vibrating spring.

When the tank body vibrates forward, the moving energy is transmitted to the material by the friction between the material and the tank body, so that the material accelerates, and the moving direction of the material is the same as the vibration direction of the tank body.

When the tank body vibrates backward, the material will continue to move forward due to the inertia, and the tank body will move backward from the bottom of the material. Due to the resistance during the movement, the material will fall over the tank body and fall back to the tank body.

When the tank vibrates again forward, the material is transported forward due to acceleration. This cycle is repeated to achieve material transport.

Structure of vibrating conveyor

Conveyor and balance chassis

The trough (carrier, trough) and balance chassis (chassis) are the two main components in the vibrating conveyor system. The tank conveys the material, and the bottom frame mainly balances the inertial force of the tank body and reduces the dynamic load transmitted to the foundation.

Exciter

The vibration exciter is the power source of the vibrating conveyor and the exciting force that generates periodic changes, and the components that continuously vibrate the trough and the balanced chassis can be classified into mechanical type, electromagnetic type, hydraulic type, and pneumatic type. The magnitude of the exciting force directly affects the amplitude of the trough.

Main vibration spring and vibration isolation spring

The main vibration spring and the vibration isolation spring are elastic elements in the vibrating conveyor system. The role of the main vibration spring: the main vibration spring supports the trough, usually an inclined installation, the oblique inclination angle is ß (vibration angle), its role is to make the vibrating conveyor have a suitable near resonance working point, which facilitates the mutual transformation of the kinetic energy and potential energy of the system. , effectively use vibration energy. The role of the vibration isolating spring: support, and can reduce the dynamic load transmitted to the foundation or structural frame.

Guide rod

The function of the guiding rod is to make the groove body and the bottom frame vibrate relative to each other perpendicular to the center line of the guiding rod, and it is connected with the groove body and the bottom frame through a rubber hinge.

Feeding device and unloading device

The feeding device and unloading device are used to control material flow, usually softly connected to the tank