Circular Motion Vibrating Screen Manufacturers

YA Type

Circular Motion Vibrating Screen

Eccentric shaft plus eccentric block vibrator, stable operation, high screening efficiency

Application and Features of YA Type Circular Motion Vibrating Screen

YA type circular motion vibrating screen has a circular motion track, which can be used for material classification in coal preparation, mineral processing, building materials, electric power and chemical industries.

YA type circular motion vibrating screen is sturdy and durable, with low vibration noise and easy maintenance.

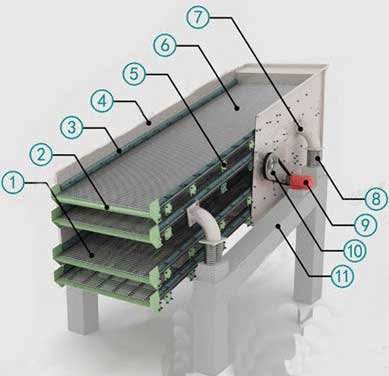

Structure of YA Type Circular Motion Vibrating Screen

YA circular motion vibrating screen is mainly composed of screen box, screen mesh, vibrator and damping spring.

- Low-stress shock-absorbing spring is adopted, and the running noise is small;

- Adopt super heavy-duty large oil clearance bearings, low operating temperature and long service life;

- Ring groove rivets and plate-type screen box frame structure are adopted, and the screen frame has high structural strength;

- Large processing capacity, strong versatility of parts and convenient maintenance.

Working Principle of YA Type Circular Motion Vibrating Screen

The YA circular motion vibrating screening machine uses the motor to pass through the triangle belt to make the eccentric block of the exciter generate a high speed. When the running eccentric block generates a large centrifugal force, it excites the vibrating screen box to produce a certain amplitude movement, and the material on the screen is tilted. The continuous throwing action produced by the impact force transmitted by the screen box on the screen surface allows the materials to pass through the particles smaller than the screen holes in the process of meeting the screen surface of the circular vibrating screen to realize the screening operation.

Selected notes

- The sieve machine of single and double, and light and heavy branches.

- The screen material is a woven net, punching sieve, polyurethane screen, etc.. If the iron grate sieve plate is according to design requirements.

- Double sieve sieve sieve size of the selected exceeds the technical characteristics and parameters of the sieve size, according to the requirements of the design.

- The motor can be mounted to the right or left, with no special requirements according to the installation diagram installation, or delivery.

- Feed box for the selection of a user, if required, can feed box.

- Selected as a change of inclination of sieve surface requirements, can be designed.

- The foundation bolts are owned by the user.

Read More: Vibrating Screen Wikipedia

Technical performance and parameters of YA circular motion vibrating screen

| Model | Screen Area m2 | Screen Inclination ° | Mesh size mm | Particle Size Range mm | Processing Capacity t/h | Motor Model | Motor Power kW | Weight kg |

| YA1236 | 4.3 | 20 | 6~50 | 200 | 80~240 | Y160M-4 | 11 | 4905 |

| 2YA1236 | 4.3 | 20 | 6~50 | 200 | 80~240 | Y160M-4 | 11 | 5311 |

| YA1530 | 4.5 | 20 | 6~50 | 200 | 80~240 | Y160M-4 | 11 | 4675 |

| YA1536 | 5.4 | 20 | 6~50 | 200 | 100~350 | Y160M-4 | 11 | 5137 |

| 2YA1536 | 5.4 | 20 | 6~50 | 400 | 100~350 | Y160L-4 | 15 | 5624 |

| YAH1536 | 5.4 | 20 | 30~150 | 400 | 160~650 | Y160M-4 | 11 | 5621 |

| 2YAH1536 | 5.4 | 20 | 30~150; 6~50 | 400 | 160~650 | Y160L-4 | 15 | 6045 |

| YA1542 | 6.5 | 20 | 6~50 | 200 | 110~385 | Y160M-4 | 11 | 5515 |

| 2YA1542 | 6.5 | 20 | 30~150 | 200 | 110~385 | Y160L-4 | 15 | 6098 |

| YA1548 | 7.2 | 20 | 6~50 | 200 | 120~420 | Y160L-4 | 15 | 5918 |

| 2YA1548 | 7.2 | 20 | 6~50 | 200 | 120~420 | Y160L-4 | 15 | 6321 |

| YAH1548 | 7.2 | 20 | 30~150 | 400 | 200~780 | Y160L-4 | 15 | 6842 |

| 2YAH1548 | 7.2 | 20 | 30~150 ; 6~50 | 400 | 200~780 | Y160L-4 | 15 | 7404 |

| YA1836 | 6.5 | 20 | 30~150 | 200 | 140~220 | Y160M-4 | 11 | 5205 |

| 2YA1836 | 6.5 | 20 | 30~150 | 200 | 140~220 | Y160L-4 | 15 | 5946 |

| YAH1836 | 6.5 | 20 | 30~150 | 400 | 220~910 | Y160M-4 | 11 | 5900 |

| 2YAH1836 | 6.5 | 20 | 30~150;6~50 | 400 | 220~910 | Y160L-4 | 15 | 6353 |

| YA1842 | 7.6 | 20 | 6 ~150 | 200 | 140~490 | Y160L-4 | 15 | 5829 |

| 2YA1842 | 7.6 | 20 | 6 ~150 | 200 | 140~490 | Y160L-4 | 15 | 6437 |

| YAH1842 | 7.6 | 20 | 30~150 | 400 | 450~800 | Y160L-4 | 15 | 6352 |

| 2YAH1842 | 7.6 | 20 | 30~150;6~50 | 400 | 450~800 | Y160L-4 | 15 | 7037 |

| YA1848 | 8.6 | 20 | 6~50 | 200 | 150~525 | Y160L-4 | 15 | 6289 |

| 2YA1848 | 8.6 | 20 | 6~50 | 200 | 150~525 | Y160L-4 | 15 | 6624 |

| YAH1848 | 8.6 | 20 | 30~150 | 400 | 250~1000 | Y160L-4 | 15 | 7122 |

| 2YAH1848 | 8.6 | 20 | 30~150;6~50 | 400 | 250~1000 | Y160L-4 | 15 | 7740 |

| YA2148 | 10 | 20 | 6~50 | 200 | 180~630 | Y180M-4 | 18.5 | 9033 |

| 2YA2148 | 10 | 20 | 6~50 | 200 | 180~630 | Y180L-4 | 22 | 10532 |

| YAH2148 | 10 | 20 | 13~200 | 400 | 270~1200 | Y180M-4 | 18.5 | 10430 |

| 2YAH2148 | 10 | 20 | 30~150;6~50 | 400 | 270~1200 | Y180L-4 | 22 | 11190 |

| YA2160 | 12.6 | 20 | 6~80 | 200 | 230~800 | Y180M-4 | 18.5 | 9926 |

| 2YA2160 | 12.6 | 20 | 6~50 | 200 | 230~800 | Y200L-4 | 22 | 11249 |

| YAH2160 | 12.6 | 20 | 30~150 | 400 | 350~1500 | Y200L-4 | 30 | 12490 |

| 2YAH2160 | 12.6 | 20 | 30~150;6~50 | 400 | 350~1500 | Y200L-4 | 30 | 13858 |

| YA2448 | 11.5 | 20 | 6~50 | 200 | 200~700 | Y180 M -4 | 18.5 | 9834 |

| YAH2448 | 11.5 | 20 | 6~50 | 400 | 310~1300 | Y200L-4 | 30 | 11830 |

| 2YAH2448 | 11.5 | 20 | 30~150;6~50 | 400 | 310~1300 | Y200L-4 | 30 | 13012 |

| YA2460 | 14.4 | 20 | 6~50 | 200 | 260~780 | Y200L-4 | 30 | 12240 |

| 2YA2460 | 14.4 | 20 | 6~50 | 200 | 260~780 | Y200L-4 | 30 | 13583 |

| YAH2460 | 14.4 | 20 | 30~150 | 400 | 400~1700 | Y200L-4 | 30 | 13096 |

| 2YAH2460 | 14.4 | 20 | 30~150;6~50 | 400 | 400~1700 | Y200L-4 | 30 | 14455 |

Read More: Guide to the Best Vibrating Screen in 2023