vibrating conveyor manufacturers

Scraper conveyor

Experts in Conveyor Vibration System. Have 30+ Years of Experience in Scraper Conveyor.

Hot Sale High-Quality Scraper Conveyor Online.

Scraper Conveyor

The scraper conveyor that uses the scraper chain to pull and transport the bulk material in the tank is called the scraper conveyor, which is the indispensable main equipment in the modern coal mining process.

Features

The scraper conveyor structure is simple, the cost is low, and the material can be fed or discharged at multiple points along the entire length direction, and the utility model is flexible.

- Scraper conveyor can transport powder, granules and small block materials horizontally or at a small inclination angle, and the horizontal transport distance is long, up to 100 meters;

- The structure is solid and can withstand the impact, impact, smashing, pressing and other external forces of coal, gangue or other materials;

- It can be used for horizontal conveying as well as inclined conveying. When transporting upward along the slope, the inclination angle of the coal seam shall not exceed 25°, and when transporting downward, the inclination angle shall not exceed 20°. When the inclination angle of the coal seam is large, anti-skid devices shall be installed;

- Multi-point feeding and multi-point unloading, without any additional feeding or unloading device

- Can run in reverse, easy to deal with bottom chain accident;

- The casing has good sealing performance, which can prevent the dust from being raised during the conveying process and reduce the pollution to the environment.

- When there is no casing at the tail, and the scraper is put into the material pile, the material can be reclaimed and conveyed by itself.

Advantage

- The structure is solid. It can withstand the external forces such as punching, smashing, smashing and pressing of coal, vermiculite or other materials.

- It can adapt to the need of unevenness and bending of the bottom surface of coal mining face, and can withstand bending in vertical or horizontal direction.

- The body is short, easy to install.

- Can double as the track of the shearer operation.

- Can be reversed to facilitate the handling of the bottom chain accident.

- Can be used as the fulcrum of the front section of the hydraulic support.

- The structure is simple, and the feeding length can be fed or unloaded at any point.

- The casing is sealed to prevent dust from flying and polluting the environment when conveying materials.

- When the tail is not provided with the casing and the scraper is inserted into the pile, it can be picked up by itself.

Structure

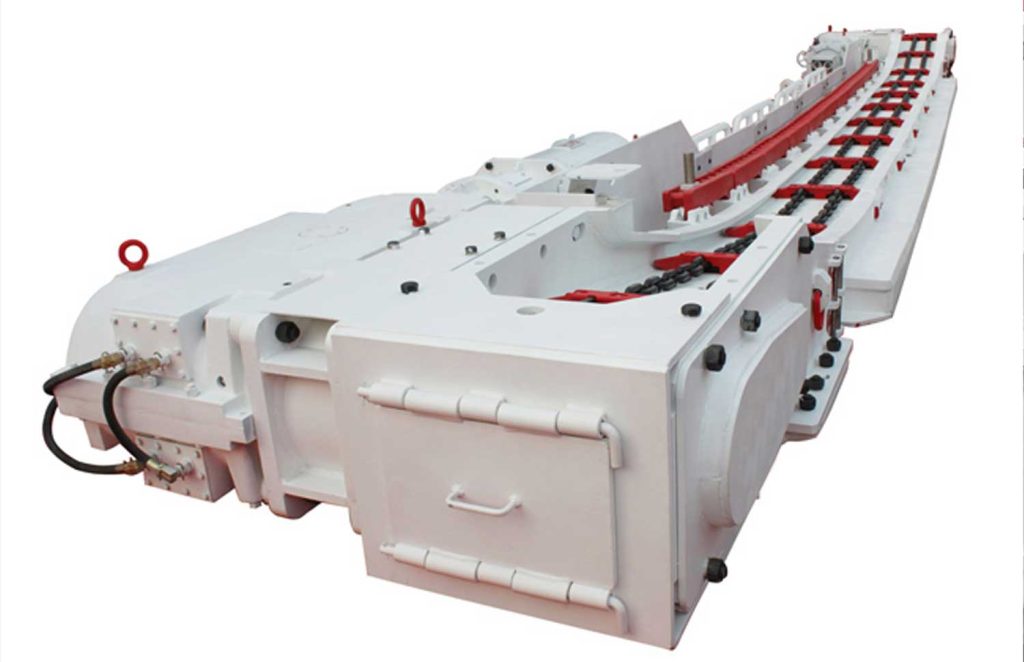

The main structure and components of various types of scraper conveyor are basically the same, it consists of three parts: the head, the middle part and the tail part.

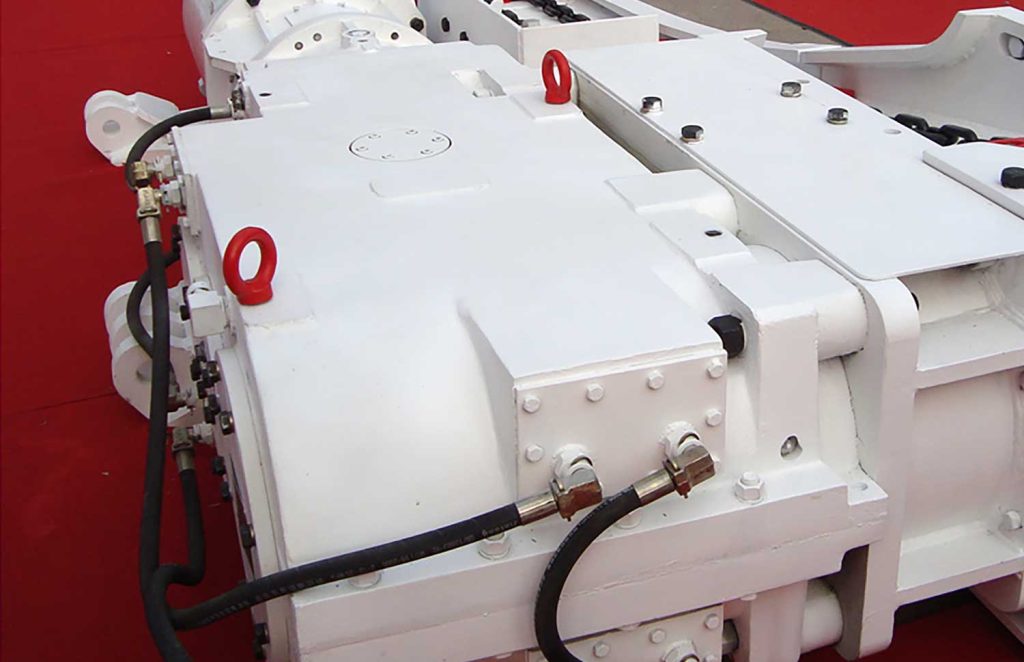

The scraper conveyor consists of a transmission system, a head frame, a head wheel assembly, a scraper chain, an intermediate groove, a discharge gate, a tail frame, a tail wheel assembly, a tensioning device, etc.

The transmission system consists of a motor, a reducer and a coupling, which is the power part of the scraper conveyor. Due to the low speed of the scraper conveyor, the reducer usually adopts the NGW type planetary gear reducer. The arrangement of the transmission system has two basic forms, which can also be adjusted according to the site location. In order to facilitate installation, a chassis for installing the motor and reducer is designed under the transmission device.

The main function of the nose frame is to support the head wheel assembly.

The head wheel assembly consists of drive shaft, sprocket, bearing and sealing and lubrication system.

PRINCIPLE

The working principle of the scraper conveyor is to use the open chute as a bearing for coal, vermiculite or material, and fix the scraper on the chain (constituting the scraper chain) as a traction member. When the head drive is activated, the sprocket on the driven head shaft rotates, causing the scraper chain to circulate and move the animal material along the chute until the machine head is unloaded. The scraper chain bypasses the sprocket for a stepless closed cycle operation to complete the material transport.

Application

Scraper conveyor is an important conveyer used to transport materials in coal mine, chemical mine, metal mine and power plant.

The scraper conveyor can transport powder, granular and small block materials such as coal powder, crushed coal, cement, fly ash, coke powder, coke particles, mineral powder, fertilizer, grain, etc. It is widely used in the coal industry, feed mills, and grain processing plants.

Specification:

| Model | Belt width(mm) | Appropriate granularity(mm) | 10% Max granularity(mm) | Maximum conveying slope angle | Material Humidity |

| FU150 | 150 | <4 | <8 | ≤15° | ≤5% |

| FU200 | 200 | <5 | <10 | ≤15° | ≤5% |

| FU270 | 270 | <7 | <15 | ≤15° | ≤5% |

| FU350 | 350 | <9 | <18 | ≤15° | ≤5% |

| FU410 | 410 | <11 | <21 | ≤15° | ≤5% |

| FU500 | 500 | <13 | <25 | ≤15° | ≤5% |

| FU600 | 600 | <15 | <30 | ≤15° | ≤5% |

How to use:

- During the start of the operation of the scraper conveyor, check the tightness of the scraper chain, because the connection between the chutes will reduce the spacing due to the operation. If the chain is too loose, there will be accidents such as chain, chain jump, chain breakage and chain drop. The inspection method is to reverse the conveyor and count the number of loose links. If there are more than two completely loose links, then Need to re-tighten the chain.

- The working surface should be kept straight. If the working surface is not straight, the tension of the two chains will be different, which will result in uneven wear of the chain or cause the bottom chain to be dropped, stuck or broken.

- The bending of the conveyor should be appropriate. Do not appear “quick bend”. The curved part should be no less than eight chutes. When moving, pay attention to the front and rear hydraulic jacks to cooperate with each other to avoid sharp bends. Otherwise, it will cause the chute to be staggered, causing the chain to be broken. It is necessary to pay special attention to the fact that the conveyor cannot be moved when it stops.

- The conveyor should be laid flat. Due to the limitation of the structure of the chute, it can only adapt to the change of 3′-5′ in the vertical direction. Therefore, if the surface of the working surface is partially uneven, it should be flattened. The flat laying of the conveyor is conducive to the operation of the scraper chain, and the chute can be reduced. Wear and reduce power consumption.

- When blasting, the transmission part of the conveyor and the pipeline, unit cable, switch, etc. must be protected. When the conveyor transports iron and long materials, safety measures should be taken to avoid personal accidents.

- The overlap between the tail of the transition groove and the middle groove is not allowed to be excessively bent, and the wooden board is used when bending.

- Pay special attention to the vibration of the coupling. Check the vibration of the hydraulic coupling when the conveyor is started. In order to protect the good heat dissipation conditions, the protective cover and liquid should be cleaned frequently.

Maintain

The detailed embodiment of the protection and protection of the scraper conveyor is to adhere to daily inspection, weekly inspection, quarterly inspection, semi-annual inspection and overhaul. The contents are as follows:

Daily inspection

- Check whether some of the transitions have abnormal signs such as abnormal sounds and severe oscillations and fever. If they are, they should be removed in time.

- Check whether the gearbox, hydraulic coupler, hydraulic cylinder and propulsion system hose can be leaked. If the leakage is serious, it should be treated in time and make up for the oil.

- (Check whether the reducer, blind shaft, sprocket, coal shield, shovel and scraper chain bolts can be loosened. If looseness is found, it should be handled in time.

- Check if the scraper, adapter ring and ring chain can be damaged. If damage is found, it should be replaced in time.

- Check if the scraper chain is tight and has the appearance of jumping teeth. If the scraper chain is too loose, it should be tensioned in time.

- Check the chute for the loss and the appearance of the wrong port. Once found, it should be replaced in time.

Weekly inspection

- Check whether the amount of oil in the gearbox, fluid coupling, blind shaft, etc. is appropriate and whether there is any change.

- Check if the bolts of the coal slab and the shovel are loose or fall.

- Check if the head (tail) frame can be damaged.

- Check the fastening condition of each connecting bolt of the machine head (tail).

- Check the wear status of the derailleur and scraper.

- Check if the motor leads are damaged.

- Check the damage and deformation of the chute retaining plate and the shoving coal.

- Check if the hydraulic cylinder and hose are damaged.

How to choose the right scraper conveyor

- Conveyor type: general models are suitable for material temperature less than 100℃; high temperature resistant scraper conveyor can transport material temperature up to 650-800℃.

- Model specifications: The model specifications of the scraper conveyor are determined according to the conveying volume required by the process, and then the length and combination of the conveyor slots are reasonably selected according to the layout of the process equipment and the conveying length.

- Scraper chain selection: Determine the appropriate scraper chain type according to the type of material. If it is to convey powdery materials, try not to use roller chains in the scraper conveyor.

Note: No matter it is conveyed horizontally or vertically, when the material enters the closed machine trough from the feeding port, under the action of external force such as the thrust of the scraper and the gravity of the material itself, the bulk material forms enough internal friction.

Notes

The scraper conveyor can be used for horizontal transport or for inclined transport. When transporting along an inclined upward direction, the inclination angle of the coal seam shall not exceed 25°. When transporting downward, the inclination angle shall not exceed 20°. When the inclination Angle of the coal seam is large, anti-skid device shall be installed. Bendable scraper conveyor allows bending of 2° ~ 4° in horizontal and vertical directions.