TH/TD

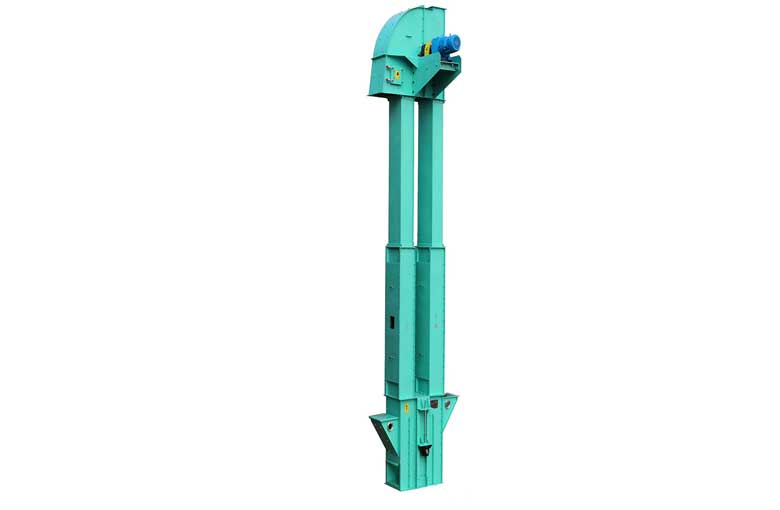

Bucket Elevator

TD bucket elevator is suitable for vertically conveying powdery, granular, and small bulk materials with low abrasiveness, such as grain, coal, cement, crushed ore, etc., with a lifting height of 40m. The TD type is designed and manufactured according to the JB3926-85 “Vertical Bucket Elevator” standard. At present, the commonly used bucket elevators in China are all vertical. TD type bucket elevator has four types of hoppers: Q type (shallow bucket), H type (arc bottom bucket), ZD type (medium deep bucket) and SD type (deep bucket). Read More: Bucket Conveyor Wikipedia

TD bucket elevator

TD bucket elevator is composed of running part (hopper and traction belt), upper section with drive roller, lower section with tension roller, middle casing, driving device, backstop brake device, etc. It is suitable for upward conveying of non-abrasive and semi-abrasive bulk materials with a loose density ρ<1.5t/m3, such as coal, sand, coke powder, cement, crushed ore, etc.

TD bucket elevator structure

Transmission device The transmission device of the TD bucket elevator has two forms, respectively equipped with a YZ type reducer and a ZQ (or YY) type reducer. The YZ type shaft reducer is directly installed on the spindle head, eliminating the need for transmission platforms, couplings, etc., making the structure compact and light in weight, and it is equipped with a special-shaped roller backstop inside, which is reliable in backstopping. The reducer has low noise, stable operation, and floats with the main shaft to eliminate installation stress.

The high-strength rubber belt as its traction component overcomes the dynamic load generated by the chain meshing drive, and can lift various powdery, granular and massive (≤30mm) materials. The material temperature is ≤120°C, which saves energy compared with ordinary elevators. 30% or more

Advantage

- Suitable for powder/granular/small lump conveying

- Good sealing, no dust pollution

- The trouble-free time exceeds 20,000 hours

- Bucket capacity: 3~102L

- Bucket speed: 1.4~1.8m/s

- Motor power: 5.5~7.5KW

- Delivery capacity: 32-686 cubic/hour

Lifting height: 100 meters (more than 80 meters need special design)

TD Bucket Elevator Features

- The driving power is small, and the inflow feeding, induction unloading, and large-capacity hoppers are densely arranged. There is almost no feeding and digging when the materials are lifted, so there is less reactive power.

- The lifting range is wide. This type of hoist has less requirements on the types and characteristics of materials. It can not only lift general powdery and small granular materials, but also can lift materials with high grinding properties. It has good sealing performance and less environmental pollution.

- Good operation reliability, advanced design principles and processing methods ensure the reliability of the whole machine operation, and the trouble-free time exceeds 20,000 hours. High lifting height. The hoist runs smoothly, so it can reach a high lifting height.

- The service life is long, the feeding of the hoist adopts the inflow type, no need to use a bucket to dig the material, and there is little extrusion and collision between the materials. The machine is designed to ensure that the materials are rarely scattered during feeding and unloading, which reduces mechanical wear and tear.

TH bucket elevator

TH ring chain bucket elevator is suitable for conveying powdery, granular and small pieces of non-grinding and less abrasive materials. TH type is a circular chain bucket elevator that adopts mixed or gravity unloading and digging loading.

Structure of TH ring chain bucket elevator

High quality alloy steel high round link chains for towing parts. The middle casing is divided into single and double channels, and the internal weight box is constantly tensioned automatically. The sprocket adopts a replaceable rim combined structure. Long service life and easy replacement of the rim. The lower part adopts a gravity automatic tensioning device, which can maintain a constant tension and avoid slipping or detachment. At the same time, the hopper has a certain degree of tolerance when it encounters jamming caused by accidental factors, which can effectively protect the lower shaft and other components.

Application of TH ring chain bucket elevator

The bucket elevator is suitable for conveying powdery, granular and small bottom grinding materials with a bulk density of less than 1.5t/m and which are easy to dig out. Such as coal, cement, crushed stone, sand, fertilizer, food, etc. TH type bucket elevator is used for vertical conveying of various bulk materials. It is suitable for conveying powdery, granular and small block materials, and the material temperature is below 250°C.

TH ring chain bucket elevator is equipped with two kinds of hoppers

TH ring chain bucket elevator is equipped with two types of hoppers: ZH type (medium-deep bucket) is generally suitable for conveying materials that are wet, easy to agglomerate, and difficult to throw out, such as wet sand, molding sand, chemical fertilizer, alkali fertilizer, alkali powder etc. SH type (deep bucket) is generally suitable for conveying dry, loose and easy-to-throw materials, such as cement, gravel, coal, etc.

TH ring chain bucket elevator transmission

TH ring chain bucket elevator transmission device has two types, which are respectively equipped with ZJ type reducer and ZQ type reducer. The ZJ type shaft-mounted reducer is directly mounted on the spindle head, eliminating the need for a transmission platform, coupling, etc., making the structure compact, light in weight, and with a special-shaped roller backstop inside, the backstop is reliable, and the reducer is noisy. Low, smooth operation, and float with the main shaft, can eliminate installation stress. The maximum conveying capacity of this machine is 365m3/h, and the maximum lifting height is 50m.

Main features of TH ring chain bucket elevator

- Easy maintenance and long service life.

- The casing steel plate is thickened and has good rigidity.

- The temperature of conveyed materials can reach up to 250°C.

- The middle casing has two forms: single channel and double channel.

- The lifting height is stable and reliable, with low noise and easy maintenance.

- The lifting capacity of the improved model is more than 30% higher than that of the ordinary model.

- The ring chain of the hoist is forged with low alloy steel and treated with carburizing and quenching, which has extremely high tensile strength and wear resistance.

Read More: Bucket Elevator, Bucket Conveyor, Best Beginner’s Guide

TD vs TH Bucket Elevator

| Type | TD | TH |

| Structure | Use rubber belt as traction member | Forged endless chain as traction member |

| Uninstall feature | Centrifugal or mixed discharge | Mixed or gravity unloading |

| Applicable delivery materials | Non-abrasive and semi-abrasive materials with a loose density ρ<1.5t/m3, powdery, granular, and small | Non-abrasive and semi-abrasive materials with a loose density ρ<1.5t/m3 in the form of powder, granular and small blocks |

| Operating temperature | The temperature of the conveyed material shall not exceed 600C, if the heat-resistant rubber belt is used, the temperature shall not exceed 2000C | The temperature of the conveyed material shall not exceed 2500C |

| Model | TD100, TD160, TD250, TD315, TD400, TD500, TD630 | TH315, TH400, THT500, TH630, (TH800) (TH1000) |

| Lifting height | About in the range of 4 to 40 | About in the range of 4.5 to 40 |

| Delivery volume | 4~238m3/h | 35~185m3/h |

TD Bucket Elevator Performance

- Transmission device: The transmission device of TD type bucket elevator has two types, which are respectively equipped with YZ type reducer or ZQ (YY) type reducer. The YZ-type shaft-mounted reducer is directly mounted on the main shaft head, eliminating the need for a transmission platform, coupling, etc., making the structure compact and light in weight, and with a special-shaped roller reverser inside, the backstop is reliable. The reducer has low noise, smooth operation, and floats with the main shaft to eliminate installation stress.

- TD-type bucket elevator has four types of hoppers: Q type (shallow bucket), H type (arc bottom bucket), Zd type (medium deep bucket), Sd-type (deep bucket).

| Bucket elevator model | TD100 | TD100 | TD160 | TD160 | TD160 | TD160 | TD250 | TD250 | TD250 | TD250 | TD315 | TD315 | TD315 | TD315 |

| Hopper type | Q | H | Q | H | Zd | Sd | Q | H | Zd | Sd | Q | H | Zd | Sd |

| Delivery capacity m³/h | 4 | 7.6 | 9 | 16 | 16 | 27 | 20 | 36 | 38 | 59 | 28 | 50 | 42 | 67 |

| Hopper volume, L | 0.15 | 0.3 | 0.46 | 0.9 | 1.2 | 1.9 | 1.12 | 2.24 | 3 | 4.6 | 1.95 | 3.55 | 3.75 | 5.8 |

| Hopper running speed m/s | 1.4 | 1.4 | 1.4 | 1.4 | 1.4 | 1.4 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 |

| Drum speed r/min | 67 | 67 | 67 | 67 | 67 | 67 | 67 | 67 | 67 | 67 | 67 | 67 | 67 | 67 |

| Bucket elevator model | TD400 | TD400 | TD400 | TD400 | TD500 | TD500 | TD500 | TD500 | TD500 | TD500 | TD500 | TD500 |

| Hopper type | Q | H | Zd | Sd | Q | H | Zd | Sd | Q | H | Zd | Sd |

| Delivery capacity m³/h | 40 | 76 | 68 | 110 | 63 | 116 | 96 | 154 | – | 142 | 148 | 238 |

| Hopper volume, L | 3.1 | 5.6 | 5.9 | 9.4 | 4.84 | 9 | 9.3 | 14.9 | – | 14 | 14.6 | 23.5 |

| Hopper running speed m/s | 1.8 | 1.8 | 1.8 | 1.8 | 1.8 | 1.8 | 1.8 | 1.8 | 2 | 2 | 2 | 2 |

| Drum speed r/min | 55 | 55 | 55 | 55 | 55 | 55 | 55 | 55 | 48 | 48 | 48 | 48 |

Table hopper capacity of hopper filled with water when the volume is filled with the actual amount of similar, it does not consider the amount of fill factor Ψ during transportation,

Specific selection should be based on material size, and seek Ψ correction value, thereby correcting the value given in the table throughput.

Nantong United Heavy Machinery Co., LTD(UHM) has always been an innovative pioneer in the technological development of vibrating machines, such as vibrating feeders, conveyors, screening, and drying. UHM is not only an equipment manufacturer but also a solution provider. Questions no matter whether bulk & granular or powder material processing, our experienced engineers are always able to offer the best solutions.