Single Mass

Vibrating Conveyor

Experts in Conveyor Vibration System. Have 30+ Years of Experience in Vibration Conveyor Systems.

Hot Sale High-Quality Single Mass Vibratory Conveyor Online from China.

Single Mass Vibrating Conveyor

Single groove dynamically balanced vibrating conveyor for power, coal, metallurgy, building materials, food and other industries

Single mass conveyor vibration system is used to complete the conveying process of powdery and granular materials, especially for fine powder materials that are difficult to transport.

For example, fly ash, cement, carbon powder, coal powder, silicon carbide, etc. are uniformly or continuously transferred from the storage bin or the funnel to the receiving device.

Has a unique delivery performance.

Feature of Single Mass Conveyor Vibration System

The structure is simple and compact, the lubrication point is less, and the lubrication point is not in contact with the material, and there is no special installation requirement, so the installation is convenient and the maintenance workload is small.

When the closed type is used, the sealing performance is good, the dusty, toxic, volatile materials are not polluted to the environment, and multi-point feeding and multi-point discharging can be realized.

Due to the resonance principle of mechanical vibration, the power consumption is low, and the power consumption is one-half less than that of the screw conveyor with the same conveying length.

Since the material jumps forward with a parabolic trajectory during the conveying process, the groove is slightly worn and the service life is more than three times higher than that of the screw conveyor.

The running noise is not more than 75dB (V).

It can be frequently started and continuously operated for a long time under the rated amplitude condition.

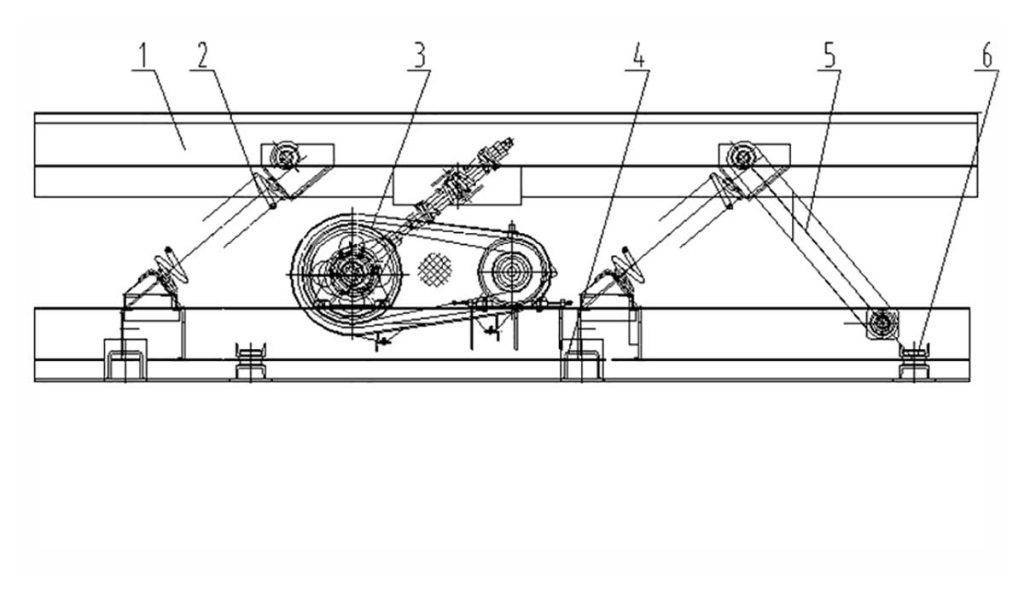

Structure

- Conveyor through

- Resonant spring

- Driving linkage

- Pedestal

- Guide bar

- Auxiliary support

Principle

Between the trough and the base chassis is coupled with the coil spring, the spring is a main vibration of the spring, the guide rod from vibrating trough role in guiding the operation of the conveyor drive mechanism for reciprocating movement of the ends of the link, and the link conveyor driven by a spring slot reciprocates the material along the direction of vibration is continuously toss jump forward, achieve the purpose of transporting materials.

Advantage

- High stiffness and simple structure, suitable for long distance and quick conveying.

- The total height is low and suitable to limited room.

- Multiple application can easily be achieved.

- Single conveyer length can reach 25 meters, and has been proved to be feasible.

- Highly Reliable, Easier Maintenance and Lower Cost.

Application:

- Suitable for electric power, coal, metallurgy, building materials, grain and other industries

- Complete the conveying process of powdery and granular materials

- Transporting wet sugar

- Fragile items such as potato chips and biscuits

- Fly ash, cement, carbon powder, coal powder, corundum are easy to dust or abrasive materials,

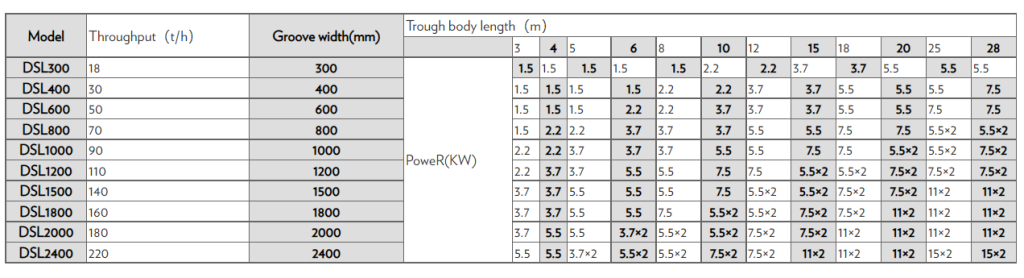

Specification

How to use:

Commissioning

After the installation and commissioning of the vibrating conveyor, the no-load continuous test run of not less than 8 hours should be carried out.

Pay attention to the changes of conveyor amplitude, working current and noise during operation.

After confirming that there is no abnormality, it can be put into normal operation.

Productivity adjustment

The Single groove dynamically balanced vibrating conveyor is a fixed-frequency fixed-width vibrating conveying device.

If the productivity of the conveyor is adjusted, the opening of the silo gate can be adjusted to change the feeding amount or change the eccentric position of the driving device. To achieve the purpose of adjusting the productivity of the conveyor.

Maintain

During the use of the vibrating conveyor, it is necessary to regularly apply grease (No. 3 calcium-based grease) to the bearing housing and the connecting rod bearing of the drive mechanism.

Continuous operation is repeated every two weeks, and non-continuous operation is filled once a month.

Always check the fastening of each fastener and replace consumables (plate springs, coil springs, rubber springs and fasteners) for long-term damage (fatigue, defects, aging wear).

It is strictly forbidden to operate with illness

Pay attention to check the temperature rise (feel) of the bearing part of the drive mechanism

If an abnormality is found, it must be stopped immediately for inspection.

Notes

Delivery amount calculated in accordance with the calculation of transport sand (bulk density of 1.6t / m3, the moisture content of 5%) level.

Conveyor installation of tank closures, liner and bulk density of the material at different power delivery to be recalculated.

Transmission distance over 15 meters, using segmented structure, site assembly connection.