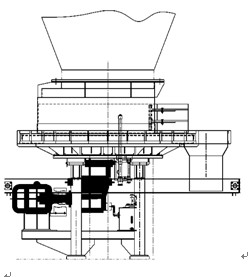

PDX Quantitative Disc Feeder

PDX quantitative disc feeder is a new type of disc feeder with high reliability, high efficiency, and energy saving, and it is a mechanical and electrical integration equipment. PDX quantitative disc feeder is composed of a quantitative disc feeder, a high-precision electronic belt scale (batching scale), and electrical instrument control. All parts work in coordination to complete batching of bulk materials. It can be widely used in iron and steel, metallurgy, building materials, the chemical industry, energy, and other industries.

A quantitative disc feeder is a volumetric feeding equipment for continuous feeding. It is installed at the discharge port of storage devices such as silos, silos, and hoppers. It depends on the gravity of the material and the function of the working mechanism of the feeder. Forced to discharge the material in the storage bin and feed it to the next device continuously and evenly. When it stops working, it can also play the role of locking the storage bin.

7 Advantages of The PDX Quantitative Disc Feeder

PDX series disc feeder mainly consists of a transmission mechanism (reducer, motor return, slewing bearing, small gear, wheel coupling, etc.), short pipe, disc base, chassis, fan-shaped door assembly (adjust the size of the discharge port ), blanking guide plate assembly (to correct the material flow direction), scraper assembly (to transfer the material to the next equipment), pipe assembly lifting device (for lifting equipment) and other components.

Advantages 1#: Not easy to Block Materials

The use of short tubes that are not easy to block and hang materials prevents the materials from being solidified and cannot be discharged smoothly due to long-term storage.

Advantages 2#: Adjustable Layer Control Gate

The adjustable material layer control gate can easily set the size of the feeding amount, the adjustment is convenient and the adjustment range is wide. And according to the process requirements, the opening of the gate can be reset at any time, and an angle-adjustable scraper device is provided to transfer the material to the next piece of equipment and play a certain role in guiding the material.

Advantages 3#: Large Carrying Capacity

The large-diameter slewing bearing structure has a particularly large load-carrying capacity, which can withstand the material pressure of the mine tank above 15 meters for a long time, and has a service life of more than 10 years, which is unmatched by other types of disc feeders. In addition, the slewing bearing has a large resistance to overturning moment and stable operation.

Advantages 4#: Good Wear Resistance

In the assembly of the short pipe, disc, scraper, and fan-shaped door, wear-resistant liners with good wear resistance are used for the parts that are in direct contact with the materials. For materials with a particle size of less than 20mm, a 20mm-thick material liner (material) is designed on the disc liner. Abrasives), prolonging the continuous normal use cycle of the disc feeder and reducing the amount of maintenance.

Advantages 5#: Good Lubrication Condition

The lubricating conditions of the running part are good. The main transmission structure such as the reducer, slewing bearing, and small wheel adopts a sealed structure to ensure that no foreign matter enters the lubricating part of the transmission mechanism. The reducer circulation lubrication system is adopted to prevent oil leakage.

Advantages 6#: High Structural Reliability

The transmission mechanism has high reliability and long service life. The energy-saving effect is better and the operation is more economical.

The reducer and the motor are installed under the disc. The whole equipment has a compact structure, reasonable layout, small space occupation, and simple foundation.

The reducer and the disc are relatively independent, and there is no need to empty the silo or remove the disc surface during maintenance, which is convenient, simple, and short maintenance period.

The closed structure is adopted, so that all the materials fall from the discharge port, and will not be scattered around the disc and inside the disc feeder.

The advanced frequency conversion stepless automatic speed regulation system can adjust the flow of materials to meet the batching requirements.

It is equipped with a dust cover and a dust removal port. After being connected to the on-site dust collection pipeline, it can prevent the dust from flying on-site and ensure a clean and comfortable working environment.

Advantages 7#: Flux Vector Control

In terms of electrical control, the frequency conversion speed regulation adopts the magnetic flux vector control method, which has the characteristics of the large driving torque, wide speed regulation range, high control precision, and stable operation. Stable operation at low speed.