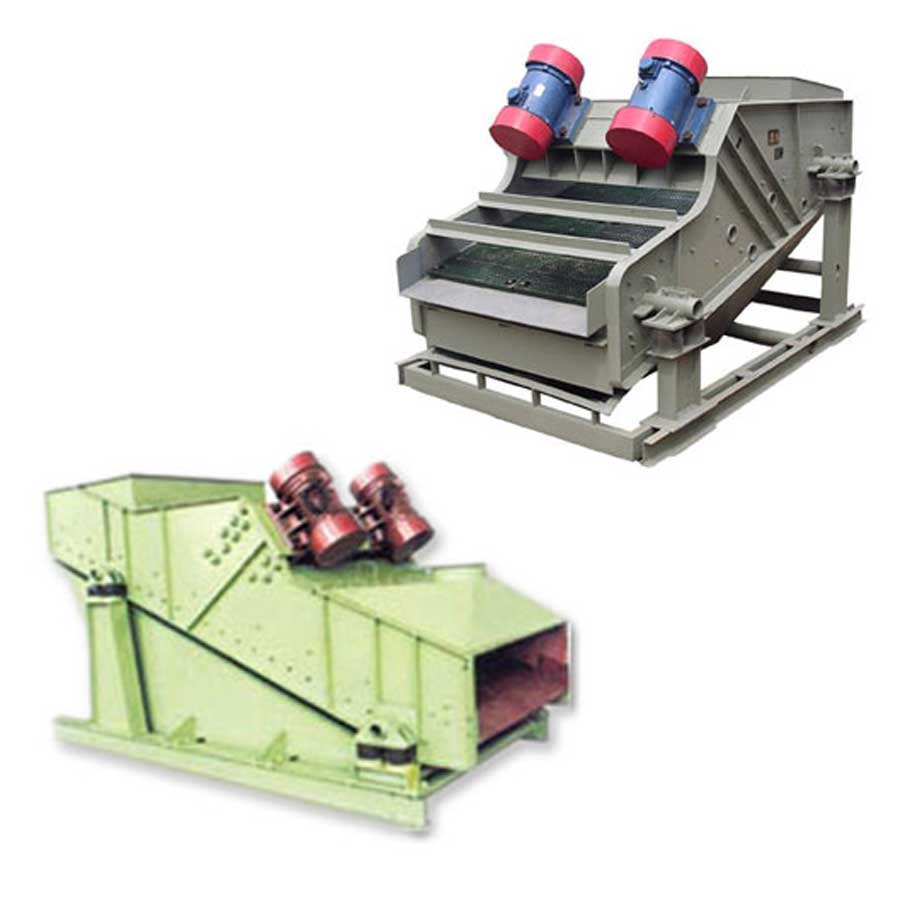

Circular and Linear Vibrating Screen

Both the linear vibrating screen and the circular motion vibrating screen can be used in the mine. The main purpose is to separate the materials with different properties so that the particle size of the material more meets the requirements of the finished product. But there are many differences between linear vibratory screens and circular motion vibrating screens in many aspects.

The oscillating motors on a linear screening deck are mounted eccentrically while the deck is inclined. These user-adjustable settings work with the machine’s linear stroke to create an elliptical pattern. The material trajectory is obviously biased towards a straight line, but gravity and inclination angles add a small amount of curved flight to the rocky chunks.

Meanwhile, on a similarly sized circular motion vibrating screen, V-belts connect the motor drive to the exciter stage. Moving the deck in a series of tight circles, the excitation stage uses centrifugal energy to throw the ore-filled aggregate stream towards the screening media.

To summarize, linear mechanisms sieve by moving in straight lines, backward and forwards. Circular screening systems move their material loads in tight circles. They use centrifugal force, while linear systems use gravity.

Circular Motion vibrating screen

The circular motion vibrating screen uses the centrifugal force generated by the rotation of the eccentric block in the vibrator to make the screen box, vibrator, and other parts perform forced continuous circular or approximate circular motion. The material is continuously thrown on the inclined screen surface with the screen box; when it is thrown, it is layered; when it falls, the particles pass through the screen.

Typically, circular motion vibrating screens are more popular, and their movement cycle and operation are more complex. Several components make this equipment function properly:

- Screen body

- Screen mesh or sieve

- Vibration source

- Base frame

- Triangle belt

- Electric motor

- Driver eccentric

- More (model dependent)

The driver eccentric moves because of an electric motor. It revolves rapidly through a triangle belt with a centrifugal force that stimulates a sieve to move circularly. The materials on the sieve receive the impulse so that the sieve provides a throwing movement on screening surfaces. The material becomes reduced in size as it passes through the screen mesh. The steep angle of throw prevents mesh blinding and permits maximum efficiency.

Since circular screeners come in several versions, it can be used to screen wet, dry, coarse, or fine particles, which makes them more suitable for a wider range of applications. Several industries that rely on screening from this machinery are mineral beneficiation plants, mining, food and fertilizer manufacturers, coal preparation plants, steel mills, and more.

Linear vibrating screen

The linear vibrating screen is widely used in the mining industry. The main difference with a linear vibrating screen is that its motion is linear. It uses the vibration motor to excite the force so that the material is thrown up on the screen and moves forward in a straight line. The screen produces several sizes of oversize and undersize, which are discharged from their respective outlets. These models typically operate with twin-vibrating motors that function in a synchronized fashion and move the centrifugal force parallel to the motor access. Centrifugal and gravity forces help throw the material in the direction it moves, which effectively reduces its size and grades it.

The linear vibrating screen has a compact structure, reasonable vibration parameters, stable movement, low energy consumption, high output, high screening and dehydration efficiency, a fully enclosed structure, no dust overflow, automatic discharge, and is more suitable for assembly line operations.

Linear vibrating screens are available in single or double deck types with sizes up to four meters wide and nine meters long. They’re known for being rugged, stable, and simple to maintain. Typical applications include primary and secondary classification, sizing, de-sliming, washing, dewatering, and hot-material screening, among others.

Different for Circular Motion Vibrating Screen and Linear Vibrating Screen?

working principle

The operation of the linear vibrating screen and the circular motion vibrating screen is realized by the motion of the screen mesh driven by the vibrating motor, but the linear vibrating screen is synchronously reversed by two motors so that the movement of the material produces an approximate linear trajectory to complete the screen. After the movement of the circular motion vibrating screen is generated by the motor, the movement of the material is approximately a circular trajectory to achieve screening.

Linear screening decks use twin motors to shove a screening deck forward and then back. At some point, the deck “kicks” the moving aggregate up into the air and forward. On landing, the cycle repeats until all ore-containing material is sieved and classified. It’s gravity that’s paired with the oscillating screening deck to drive the ore sifting process.

Now, upon shifting over to a circular motion vibrating screen, gravity is removed from the material sieving formula. Instead of gravitational forces, centrifugal energies provide the loose aggregate with trajectory.

dual-axis and single-axis

The linear vibrating screen is also called dual-axis vibrating screen because its exciter is composed of two shafts, and uses dual motors as excitation force for operation;

The circular motion vibrating screen is also called a uniaxial vibrating screen because the exciter has only one axis, and the eccentric block is used as the exciting force.

plugging phenomenon

The material of the linear vibrating screen moves in a straight line on the screen surface. If the material is unevenly fed or the moisture viscosity of the material is high, it is easy to block holes.

The material of the circular motion vibrating screen is thrown up to make a circular motion, so the material is relatively dispersed and has a large bouncing force. Even if it is stuck in the screen hole, it can jump out, which greatly reduces the blockage rate of the screen hole.

Installation inclination is different

The installation inclination angle of the linear vibrating screen is small, and the small inclination is convenient for process layout;

The circular motion vibrating screen is installed with a large inclination angle, usually around 15-20°, thereby changing the moving speed of the material and improving the screening efficiency to a certain extent.

Materials

The material selection of linear vibrating screens is mainly light plates or stainless steel plates.

The material of the circular motion vibrating screen is thicker, and the body is made of manganese steel, which can be used to resist the impact force of the material during the screening process and prolong the service life of the equipment.

Shapes and structures

The vibration exciter of the linear vibrating screen is set under the machine, and the body can adopt a fully enclosed structure, and there is no dust overflow in the whole process, which is more conducive to the protection of the environment;

The exciter of the circular motion vibrating screen is arranged above the center of gravity of the screen box, which is conducive to the rapid dispersion of materials, and the processing capacity per unit time is higher than that of the linear vibrating screen.

Who is better

It does not make much sense to say that the linear vibrating screen is easy to use or the circular motion vibrating screen is easy to use. The key is to choose the appropriate equipment according to your actual situation, in order to make the best use of everything and achieve the effect of getting twice the result with half the effort.

Application

The linear sieve mainly screens fine particles, materials with light specific gravity and low hardness, mainly dry powder, fine particles, or micro powder materials, which are usually widely used in the food, chemical, building materials, and pharmaceutical industries. The circular motion vibrating screen is mainly used to screen materials with large specific gravity, large particles, and high hardness, and is widely used in mining industries such as mines, coal, and quarries. In addition, some difficult-to-screen materials can also use a circular motion vibrating screen.

Generally speaking, circular screeners are made of tougher materials. Manganese steel housings are required to contain high-energy centrifugal energies. Linear vibrational screening decks are built from dense carbon steel sheets. They process fine particle aggregates and smaller rocky loads. Back with a circular motion vibrational deck, centrifugal forces are preferred when screening high-hardness ores and larger material chunks. Finally, from a manufacturer’s point of view, both equipment screening types have their roles to play. Linear solutions are adaptable and find more homes in factory environments. Elsewhere, better at classifying heavier aggregates, circular screening equipment dominates mining applications.

It’s the trajectory envelope that defines each of the two vibrational screening systems. When straight-line particle sieving is needed, linear oscillation takes charge. For everything else, circular screening is the go-to material classification system. Incidentally, thanks to the higher trajectories, circular screening equipment has a superior “plugging” avoidance feature.

How to choose the right vibrating screen for your need?

If you need to screen materials with finer particle size, it is recommended to use a linear vibrating screen. The screening mesh of the linear vibrating screen can reach 400 meshes, which can screen out 7 kinds of materials with different particle sizes; If your factory is large and has high production requirements, it is recommended to choose a circular motion vibrating screen. The circular motion vibrating screen uses an eccentric block as the exciting force, so the exciting force is strong, and then performs circular motion to make the screening more efficient. higher output; If your factory is small and there is not much output demand, you can choose a linear vibrating screen. If you have a small output and a piece of large equipment, it is not a good thing to make the machine run without load for a long time. It not only does not reflect its value but also causes power waste.

Choose according to material characteristics

Each material that needs to be screened has its own unique properties, so choose a vibrating screen suitable for screening the material according to the different properties of the material. These attributes include density, shape, temperature, viscosity, particle size, mobility, particle size distribution, corrosiveness, etc. According to your different materials, you need to choose different vibrating screens. If you are not sure about this, you can ask the manufacturer’s technicians to help you.

Choose according to processing capacity

- When the required processing capacity is small, some light linear vibrating screens are cheaper and meet the demand; when the required processing capacity is large, a steel frame is required to ensure the quality. The steel frame of the mine linear vibrating screen can meet the requirements.

- According to the size of the vibrating screen and the rated processing capacity, select a vibrating motor or a vibrating exciter of appropriate power.

- Choose different sieve plate angles according to the nature of the material and the processing capacity requirements.

Choose according to the structure of the screen

When selecting a vibrating screen, the screen area and number of layers, the shape, size, and area rate of the screen hole, as well as the motion model of the vibrating screen, the vibration frequency, amplitude, and other factors should also be considered when selecting the vibrating screen. The screening efficiency of the vibrating screen is related to the movement form of the screen surface, so the screening efficiency of the fixed screen is relatively low, and the screening efficiency of the moving screen is relatively high. For the moving screen, the vibration of particles on the screen surface close to the vertical screen hole direction has a high vibration frequency and a better screening effect; if the particles slide in the direction of the screen surface, the screening effect is relatively poor.