Rotary Vibrating Screen used for different size material screening. It can be worked semi-auto or automatically with simple operation.

6 Key Parameters of Vibratory Screener

Specifying the right vibratory screener involves making sure the manufacturer understands the production goals and is supplied with complete application data, which includes information such as material type, top particle size, particle shape, application type (wet or dry), and the method of material feed. Some of the more detailed information a manufacturer needs is the following:

- Important Parameter 1: Maximum feed rate in lb/hr, ton/hr, or metric ton/hr

- Important Parameter 2:Bulk density of the material to be screened in lb/cu ft or kg/cu m meter

- Important Parameter 3: Screen opening(s) required to make the specific separation(s)

- Important Parameter 4: A sieve analysis (particle size distribution or gradation) of the feed material

- Important Parameter 5: Percentage of moisture in the feed material

- Important Parameter 6:Type of screening media preferred, i.e., woven cloth, perforated plate, urethane, grizzly bars, profile (wedge) wire, etc.

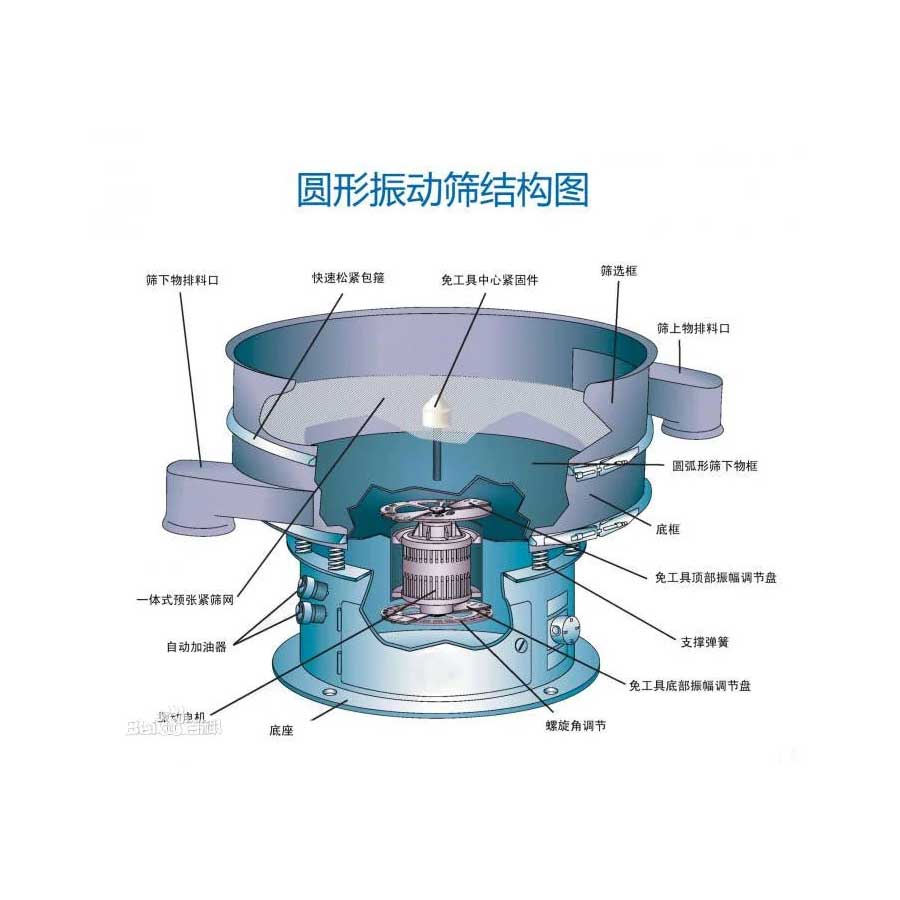

What is a rotary vibrating screen?

The rotary vibrating screen is a high-precision fine powder screening machine with low noise and high efficiency. It takes 3-5 minutes to change the screen quickly. The rotary vibrating screen uses a vertical motor as the excitation source. The upper and lower ends of the motor are installed with eccentric weights, which convert the rotary motion of the motor into the three-dimensional motion of horizontal, vertical and inclined, and then transmit this motion to the screen surface. . Adjusting the phase angle of the upper and lower ends can change the movement track of the material on the screen surface.

Application

A vibratory screener is a piece of equipment used to separate materials by particle size, remove small amounts of oversized materials from fine material, or remove excess liquid from finished products. Screeners are used in industries as diverse as food, pharmaceutical, chemical, coal, minerals, wood pelleting, asphalt, and many more. Using gravity and motion and along with mesh screens, these units perform the work of several people in a fraction of the time.

Manufacturers offer multiple vibratory screeners to handle separation and sizing of materials or removal of unwanted materials from a batch. These durable and cost-effective units are usually custom-built using a variety of screening media with screen openings ranging from 20 microns to 4 in., depending upon the product.

Working principle of rotary vibrating screen

Description

The rotary vibrating screen uses a vertical motor as the excitation source, and eccentric weights are installed at the upper and lower ends of the motor to convert the rotary motion of the motor into the three-dimensional motion of horizontal, vertical and inclined, and then transmit this motion to the screen surface.

The material is made to do outward expansion involute motion on the screen surface, so this series of vibrating screens are called rotary vibrating screens. A rotary vibrating screen has the advantages of a long trajectory of material running and a high utilization rate of the screen surface. Adjusting the phase angle of the upper and lower ends of the weights can change the movement trajectory of the material on the screen surface. It can perform fine screening and probability screening of materials.

Content

After the rotary vibrating screen is started, its power device is the eccentric blocks at the upper and lower ends of the vibrating motor with different phases.

Due to the high-speed placement, a composite inertial force is generated. Under the action of the sieve, it continuously reciprocates and then drives the screen surface to vibrate periodically, so that the materials on the screen surface move in a directional and active manner with the screen box, during which materials smaller than the screen surface aperture fall to the lower layer through the screen holes, become the material under the sieve, and the material larger than the aperture of the sieve surface is discharged from the discharge port after continuous jumping motion, and finally, the screening work is completed.

The motion trajectory of the vibrating body of the rotary-vibrating screen is a complex three-dimensional curve in space. The projection of this curve on the horizontal plane is a circle, and the projection on the two vertical planes is two identical ellipses.

In practical application, by adjusting the relative phase of the eccentric blocks at the upper and lower ends of the vibration motor, the movement trajectory of the material on the screen surface can be changed, so as to achieve different screening operations.

5 Features of the rotary vibrating screen

- Small in size, lightweight, and easy to move, the direction of the discharge port can be adjusted arbitrarily, and the coarse and fine materials are automatically discharged, which can be automated or manually.

- With high screening accuracy and high efficiency, any powder, granule, and mucus can be used.

- The screen is not blocked, the powder is not flying, the sieving can reach 500 mesh (28 microns) and the filtration can reach 5 microns.

- Unique grid design (sub-mother type), long-term use of the screen, easy to change the screen, only 3-5 minutes, simple operation, and easy cleaning.

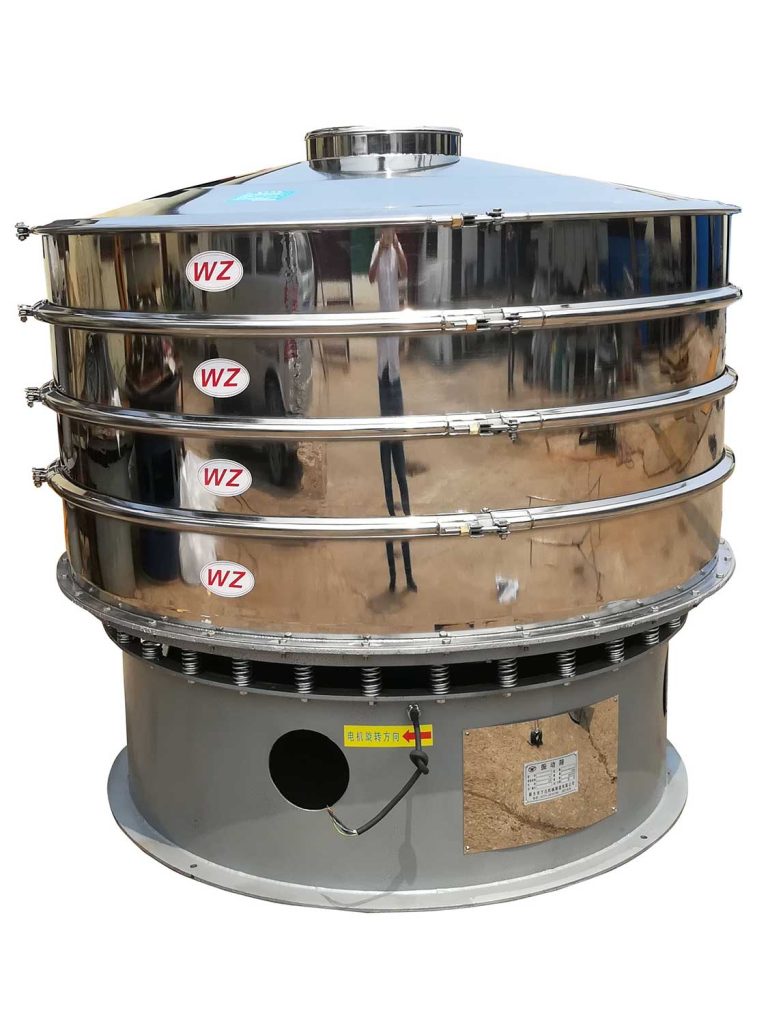

- No mechanical action, easy maintenance, single-layer or multi-layer use, and the parts in contact with materials are made of stainless steel (except for medical use).

6 Advantages of Rotary Vibrating Screen

- Improve product quality – Eliminate oversize and contamination from your powder or liquid slurries

- Increase production rate – Our screeners achieve a higher throughput capacity than standard vibrating screens

- Small footprint –The compact form requires minimal headroom to easily fit into your existing production line

- Cut cleaning downtime – A tool-free, quick-release mechanism allows for easy disassembly and cleaning

- Eliminate dust and fumes – The enclosed sanitary screener ensures the total containment of screened materials

- Reduce noise levels – Rubber suspension system dampens mechanical noise, ensuring quiet operation

8 Application of the Rotary Vibrating Screen

- All kinds of powder industry Any particle, powder, and mucus can be screened within a certain range.

- Industry: resin powder, pigment, washing powder, micro powder, paint, soda ash, lemon powder, rubber, plastic, etc.

- Abrasives, ceramic industry: alumina, quartz sand, mud, spray soil particles.

- Food industry: sugar, salt, alkali, monosodium glutamate, milk powder, soy milk, yeast, fruit juice, soy sauce, vinegar, etc.

- Paper industry: coating paint, clay mud, black and white liquid, waste liquid, paper making liquid, wastewater recycling.

- Metallurgical industry: titanium oxide, zinc oxide, electromagnetic materials, metal powder, electrode powder, etc.

- Pharmaceutical industry: Chinese medicine powder, Chinese medicine liquid, Western medicine powder, Western medicine liquid, Chinese and Western medicine granules, etc.

- Environmental protection: garbage, human and animal manure, waste oil, food wastewater, wastewater processing, etc.

How to Install the Rotary Vibrating Screen

Prepare

- Check whether the motor signs meet the requirements.

- Use a 500-volt megger to measure the insulation resistance. The value should be dried for the stator winding, and the drying temperature should not exceed 120 °C.

- Check the fasteners of the motor to prevent loosening.

- Check whether the motor surface is damaged or deformed.

- Check whether the rotation is flexible. If there is any abnormality, it should be excluded.

- Check the power supply, whether there is a phase loss, and run it for 5 minutes with no load.

Installation and Adjustment

- The motor should be fastened on the installation surface, and the installation surface must be smooth and flat.

- The motor can be installed horizontally.

- The four-core rubber cable YZ-500V is used for the lead wire of the motor. When connecting the power supply, the lead wire and cable are not allowed to have a sharp break and are reliably fixed with the vibrating body.

- The motor should be grounded reliably. There is a grounding device in the motor, and the lead end has a mark. It can also be grounded with solid bolts on the feet.

- Adjustment of exciting force.

What is the Daily Maintenance of the Rotary Vibrating Screen

Before start

- Check the coarse filter and fine filter for damage

- Whether each set of collars is locked

At startup

- Watch out for any unusual noises

- Is the current stable?

- Whether the vibration is abnormal

After use

- Clean it up after every use.

- Regular maintenance

- Regularly check whether the coarse mesh, fine mesh, and Spring are fatigued and damaged, whether all parts of the Fuselage are damaged due to vibration, and whether the parts that need to be lubricated must be lubricated.