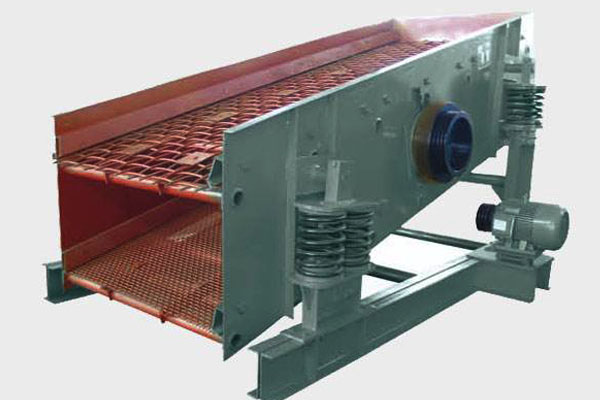

Vibrating Screen

UHM Vibrating Screens are ideal for sorting, classifying, sizing, separating, and dewatering large and fine materials.

What is Vibrating Screen

Vibratory screens separate bulk materials.

Vibratory screen works by using the reciprocating rotary vibration generated by the vibrator excitation.

The upper rotating weight of the vibrator causes the screen surface to generate plane whirling vibration, while the lower rotating weight causes the screen surface to generate conical surface rotation vibration.

Where are vibrating screens used?

Vibrating screen is suitable for processing across a wide range of applications and industries, they are used to separate feeds containing solid and crushed ores down to approximately 200 μm in size, and are applicable to both perfectly wetted and dried feed, including heavy quarry product and metal alloys; food and candy; plastics, glass, grain, and more.

vibrating screen type

The vibrating screen is mainly divided into a linear vibrating screen and a circular motion vibrating screen.

Linear vibrating screen : material moves linearly forward on the screen surface

Circular motion vibrating screen : material circular motion on the screen surface

Circular Motion Vibrating Screen

The Circular Motion Vibrating Screen is a versatile piece of equipment having the capacity to screen a wide range of minerals. It is widely used for segregating minerals such as aggregate, sand, coal, coke, slag, sinter, refractories, and urea and in various crushing and screening plants.

Read More: Circular Motion Vibrating Screen

Linear Vibrating Screen

Linear vibrating screens are classic and general screening equipment, they use twin motors to shove a screening deck forward and then back. The ore is thrown up on the screening media surface and moves forward in a straight line, so as to achieve the purpose of screening and grading the ore. Linear vibrating screens have the characteristics of low energy consumption and high screening precision. The highest screening mesh is 400 mesh, which can screen out 7 kinds of materials with different particle sizes.

Read More: Linear Vibrating Screen: Basics, Principle, Features

Gyratory sifter

- All components are easily accessible and removable for ease of disassembly and cleaning.

- No vertical vibration, longer life span of mesh (6 – 12 months).

- Every layer is installed an anti-blocking and cleaning facility and able to clean mesh while sieving.

- Exterior is designed for easy cleaning. Exterior permanent joints are either welded continuously, or strip welded and filled with epoxy.

- Lower headroom permits operation in confined areas, reducing cost of building and maintenance.

- Less conveying equipment is required for elevating material to the feed point.

- Greater product yields at higher production rates.

- Low energy consumption.

- High screening efficiency.

- Create low noise pollution.

Work Principle of Vibrating Screen

Linear vibrating screen

The linear vibrating screen is driven by a double exciter. When the two exciters are synchronized and reversely rotated, the exciting force generated by the eccentric block cancels each other in a direction parallel to the motor axis, in a direction perpendicular to the motor shaft. The stack is a combined force, so the movement of the sieve machine is a straight line.

The two motor shafts have an inclination angle with respect to the screen surface. Under the combined force of the excitation force and the material self-gravity, the material is thrown up and jumped forward in a linear motion on the screen surface, thereby achieving the purpose of screening and classifying the materials.

Circular motion vibrating screen

The circular motion vibrating screen mainly comprises a sieve box, a screen mesh, a vibrator, a vibration-damping spring device and a chassis.

The side plate of the circular motion vibrating screen is made of high-quality steel plate. The side plate is connected with the beam and the vibration stirrer base by high-strength bolts or ring groove rivets. The cylindrical eccentric shaft exciter and the partial block are used to adjust the amplitude.

The vibrator is mounted on the side plate of the circular motion vibrating screen box, and is driven by the motor through the V-belt to generate high-speed rotation of the exciter eccentric block, which generates a large centrifugal inertial force, and stimulates the screen box to generate a circular motion of a certain amplitude. The material is subjected to a continuous throwing motion by the impulse transmitted from the screen box on the inclined screen surface, and the particles smaller than the sieve holes are sieved in the process of meeting the screen surface, thereby achieving classification.

Structure of Vibrating Screen

The vibrating screen generally consists of a vibrator, a screen box, a support or suspension device, a transmission device and the like.

Vibrator

The vibrators of the single-axis vibrating screen and the two-axis vibrating screen are generally classified into two types according to the eccentricity reconfiguration. The configuration of the eccentricity is better in the block eccentric type.

Screen box

The screen box is composed of a screen frame, a screen surface and a pressing device. The screen frame is made up of side panels and beams. The screen frame must be rigid enough.

Support device

The support device of the vibrating screen has two types: a hanging type and a seat type. The seat type installation is relatively simple and the installation height is low, and it is generally preferred. The support device of the vibrating screen is mainly composed of elastic members, and coil springs, leaf springs and rubber springs are commonly used.

Transmission

The vibrating screen usually adopts a V-belt transmission device. The structure of the vibrating screen is simple, and the number of revolutions of the vibrator can be arbitrarily selected, but the belt is easy to slip during operation, which may cause the screen hole to be blocked.The vibrating screen is also directly driven by a coupling. The coupling can maintain the stable number of revolutions of the vibrator, and the service life is long, but the number of revolutions of the vibrator is difficult to adjust.